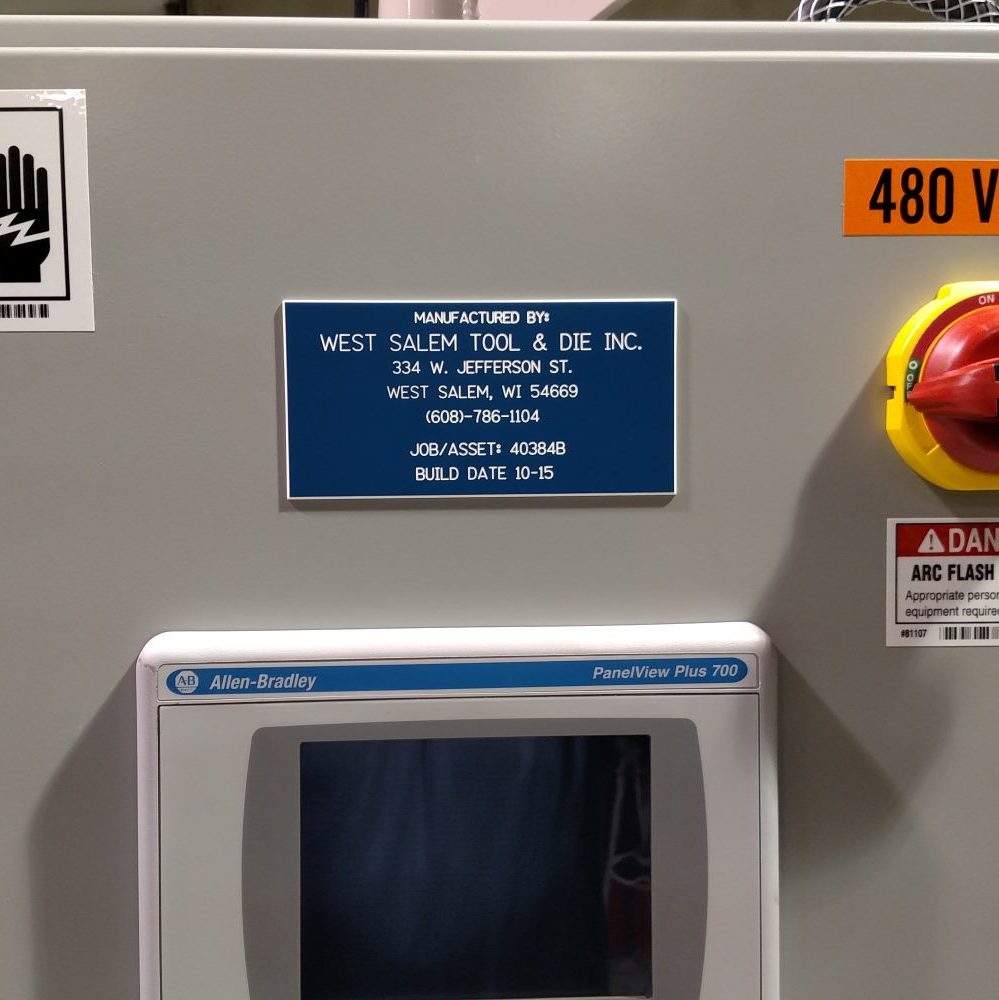

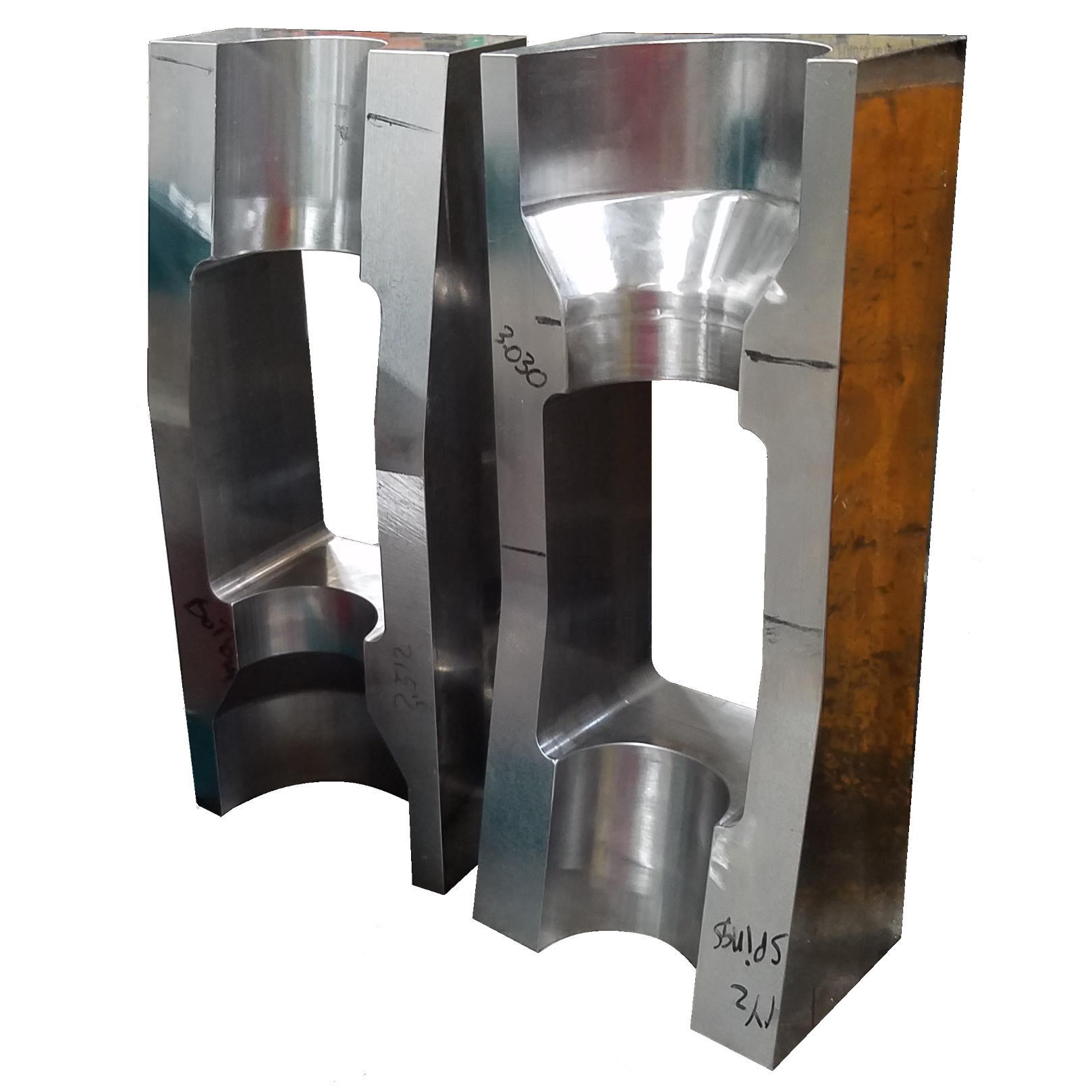

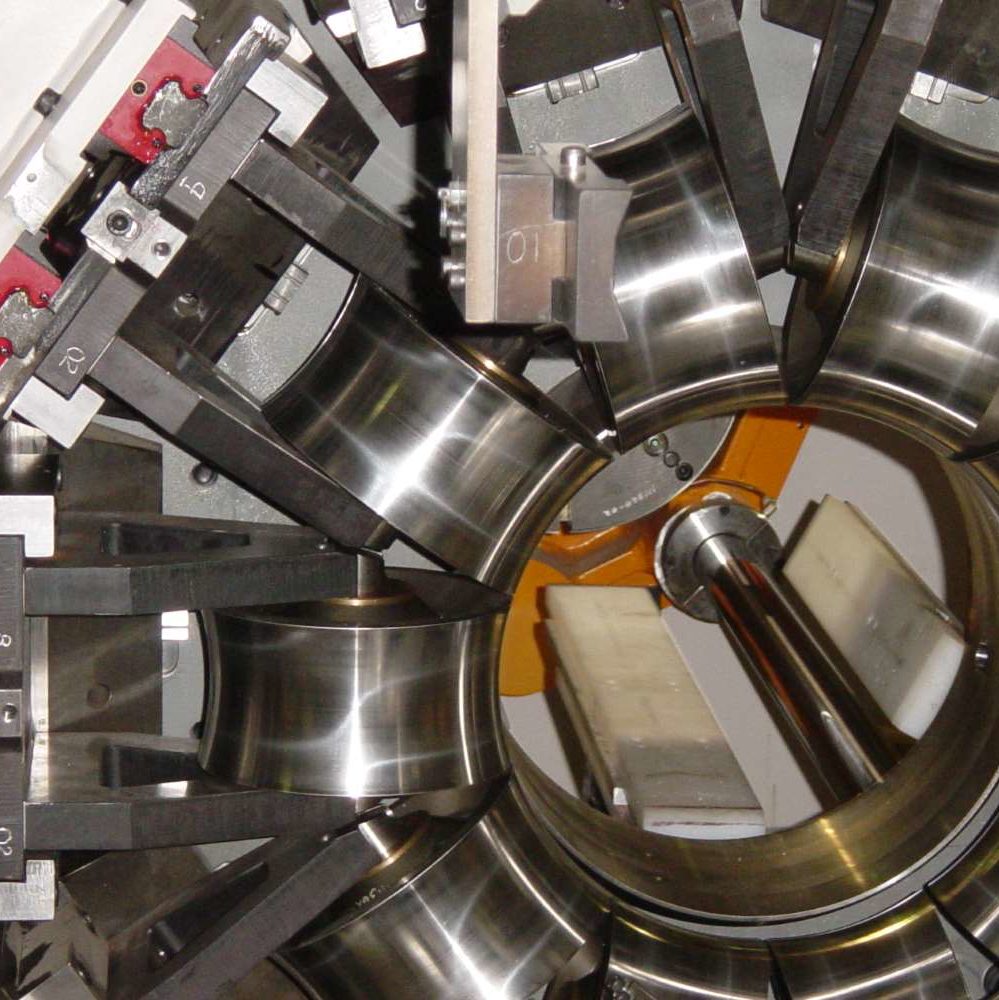

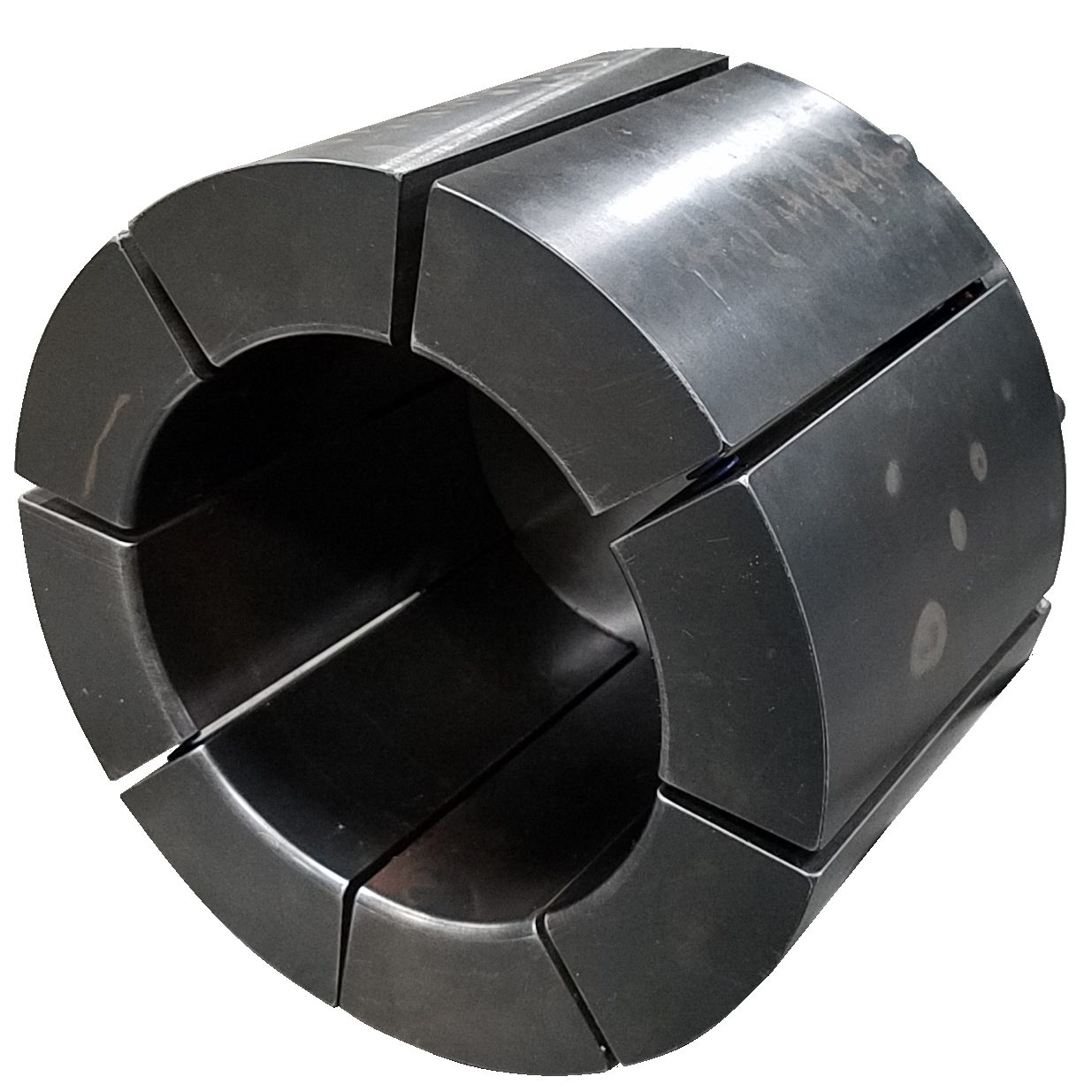

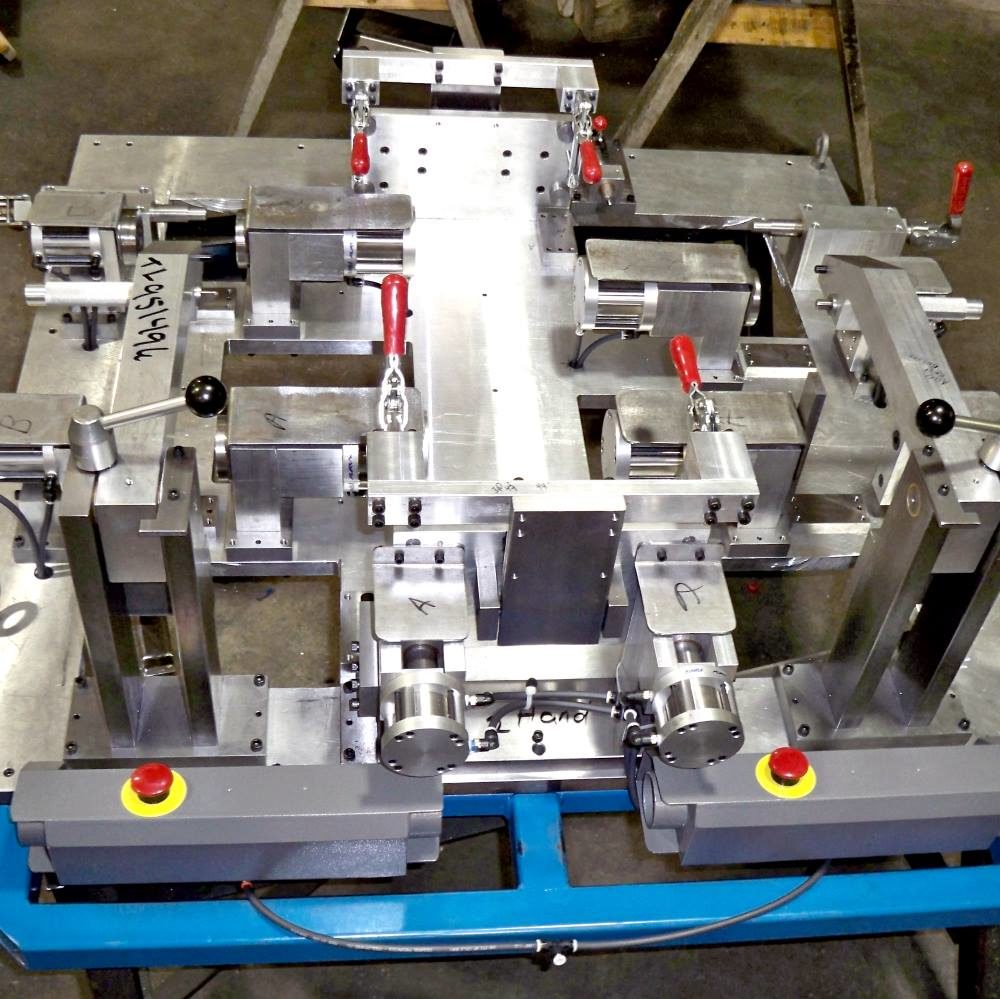

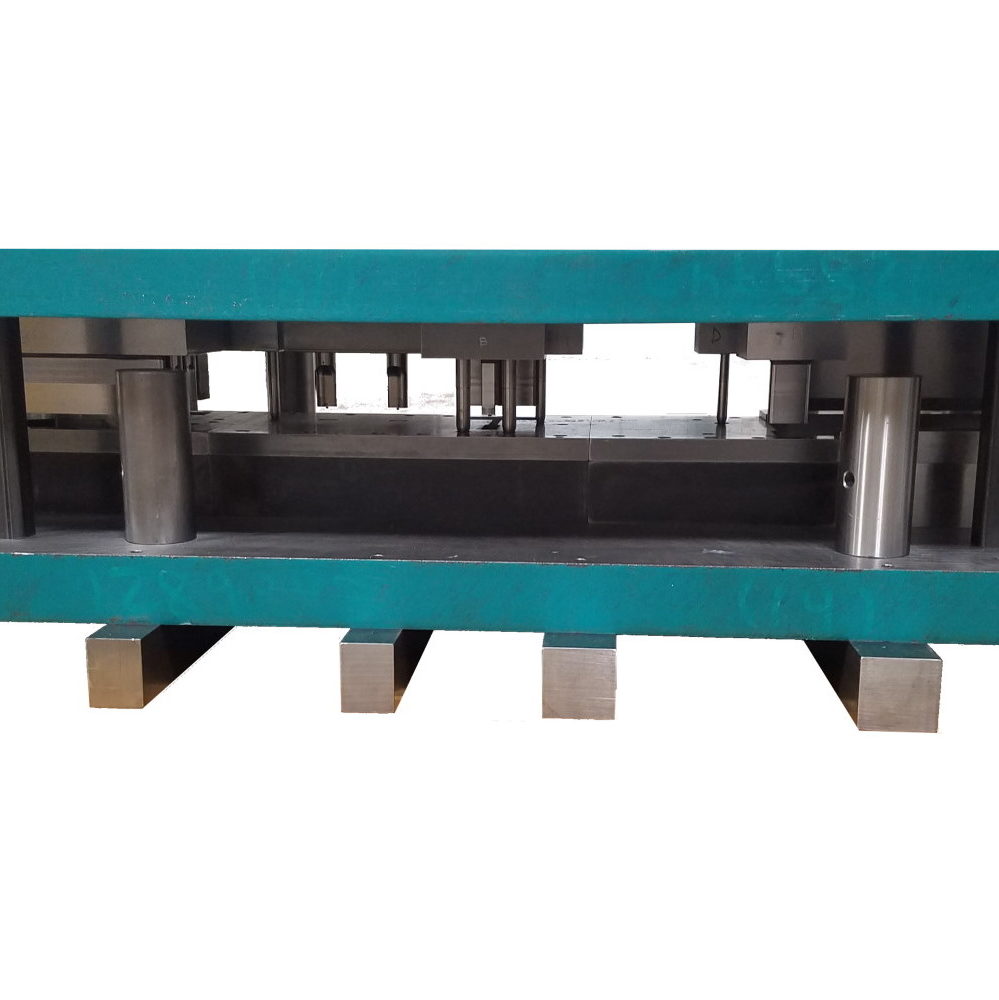

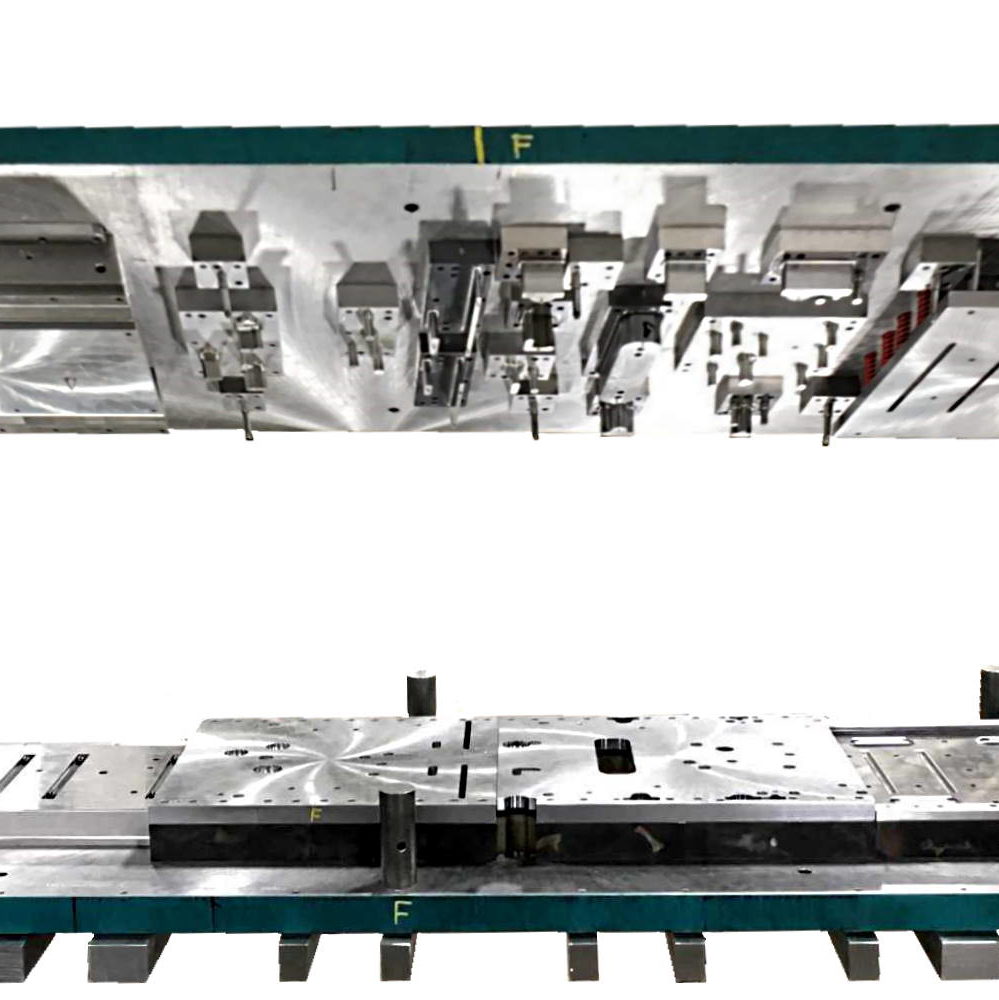

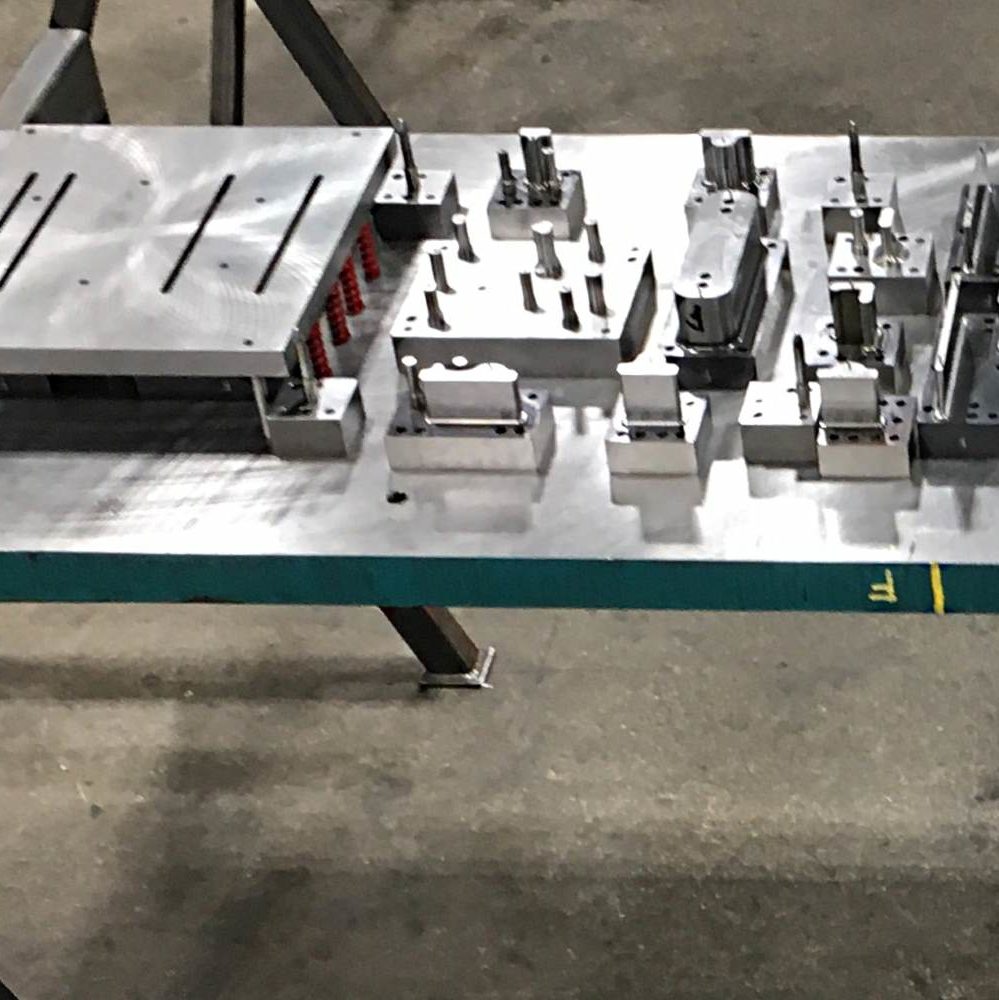

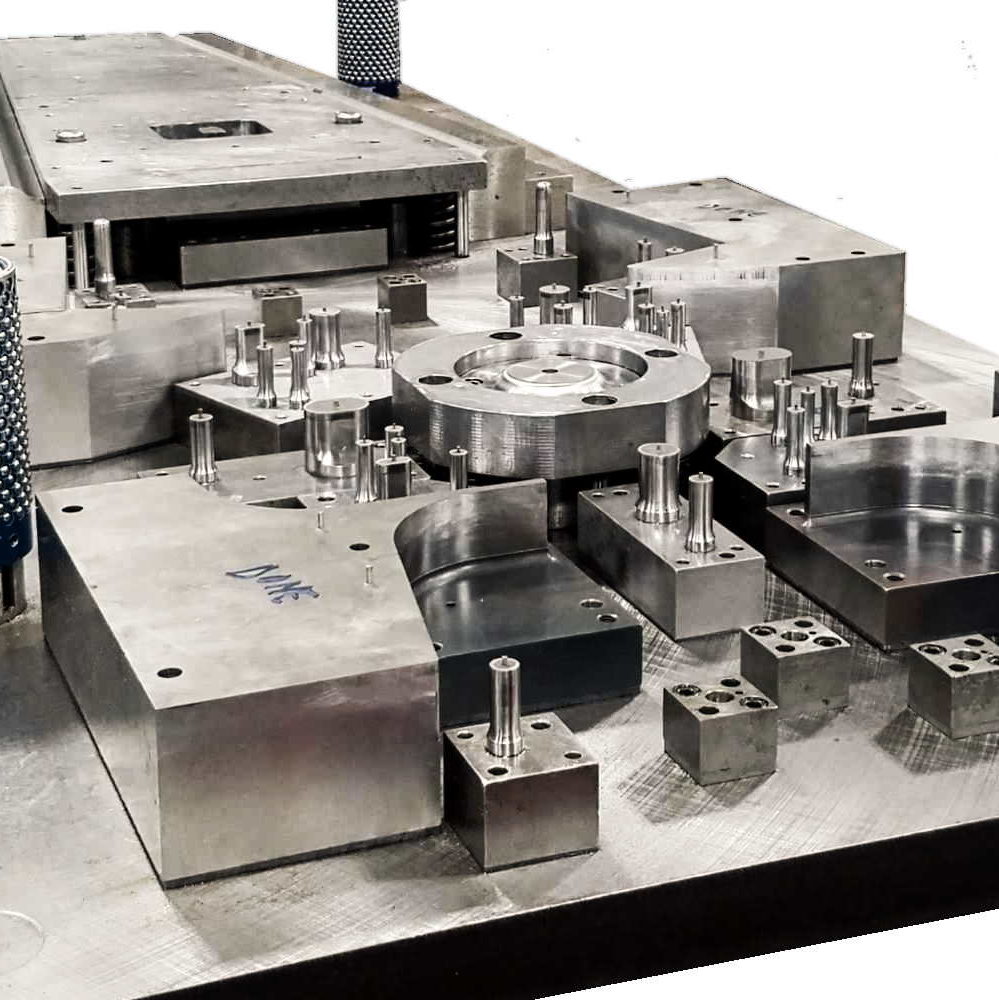

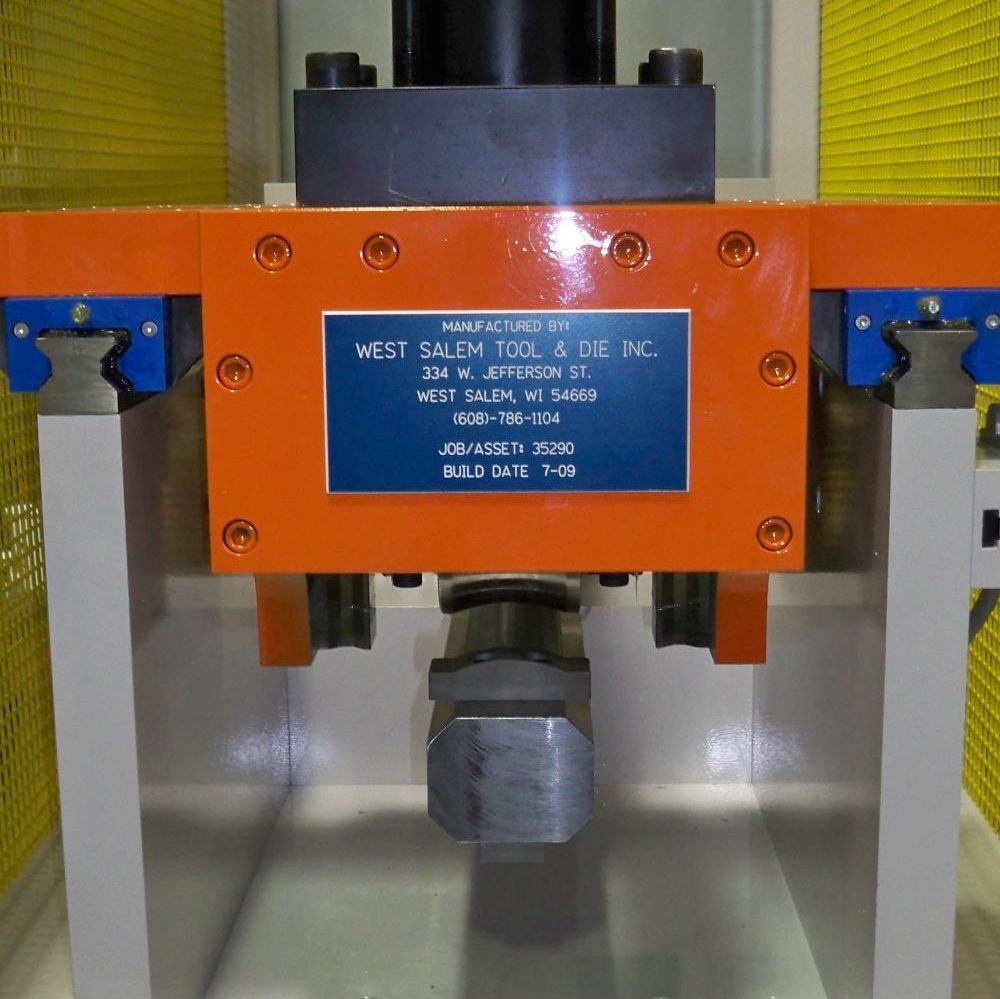

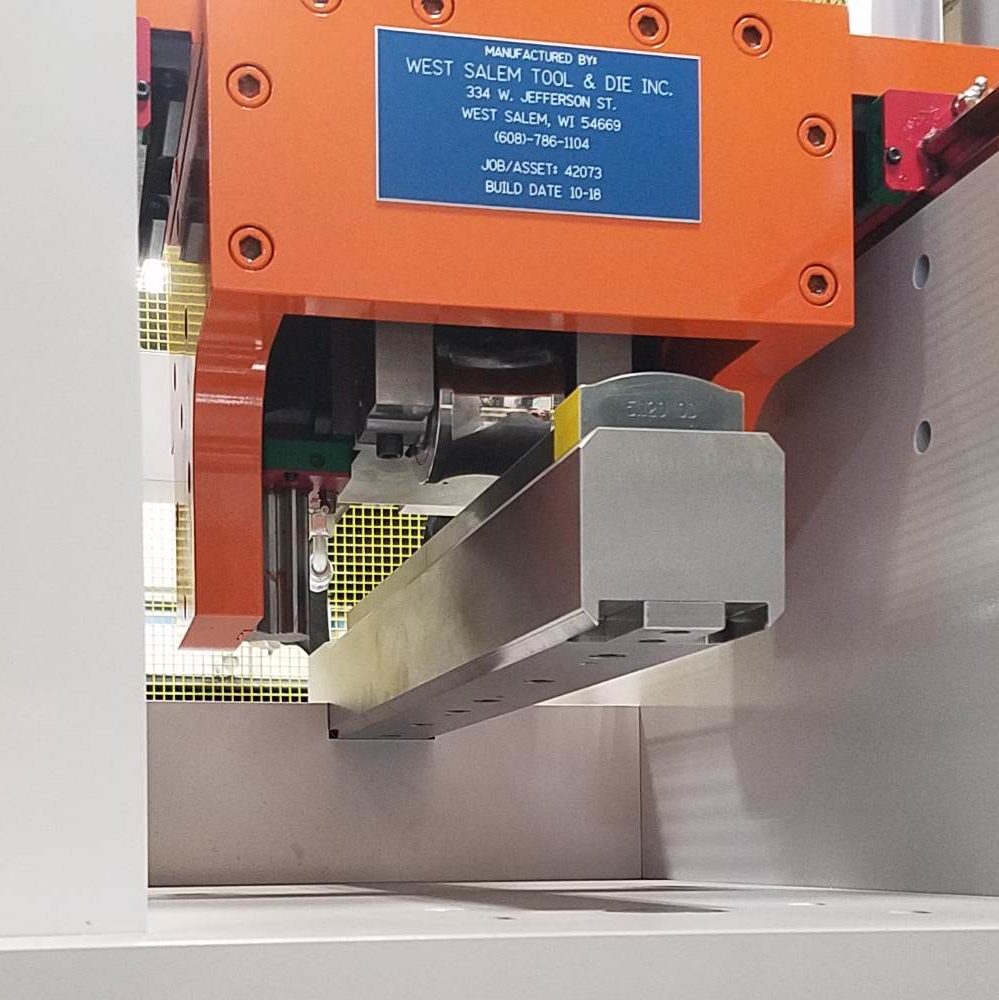

With over half a century of experience in precision tool and die services, West Salem Tool & Die designs and builds the highest quality custom equipment and tooling to industrial customers across Wisconsin, Minnesota, Iowa and beyond.

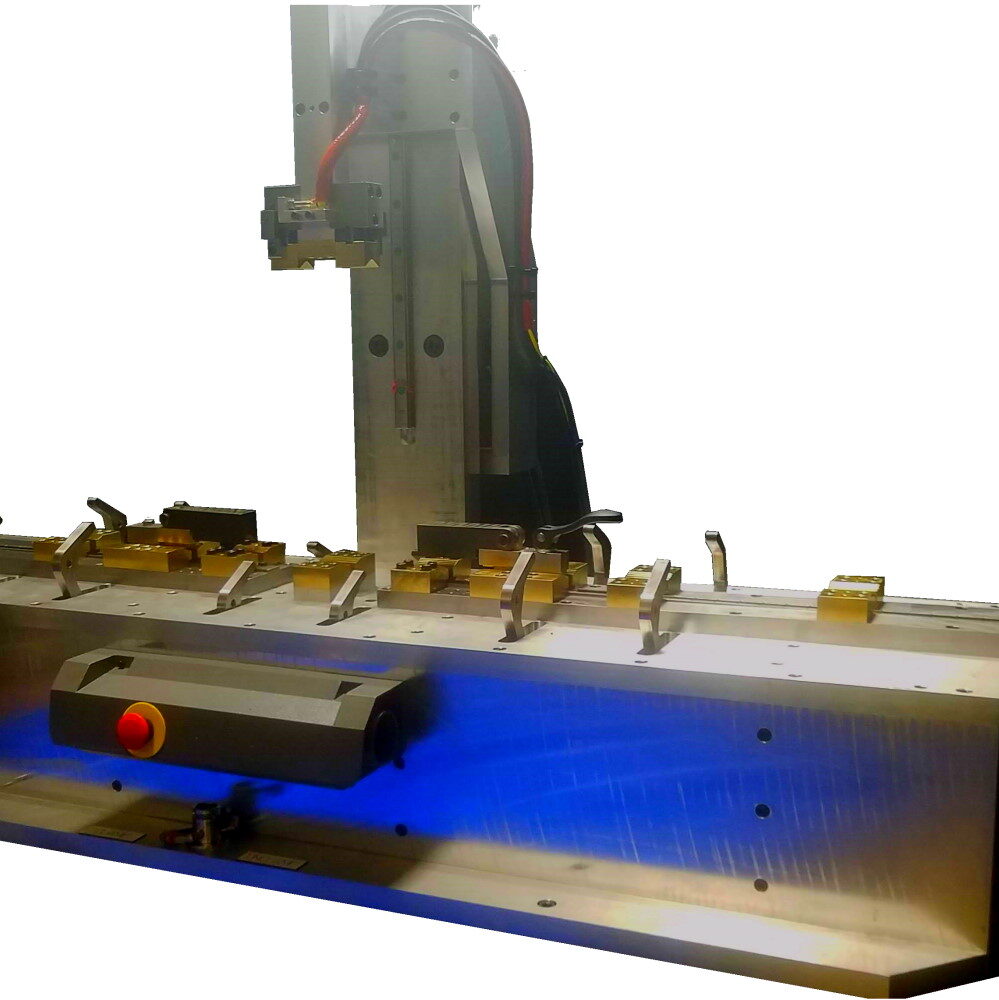

For a closer look at our products and capabilities, look at our youtube channel, where we post short clips of new machines.

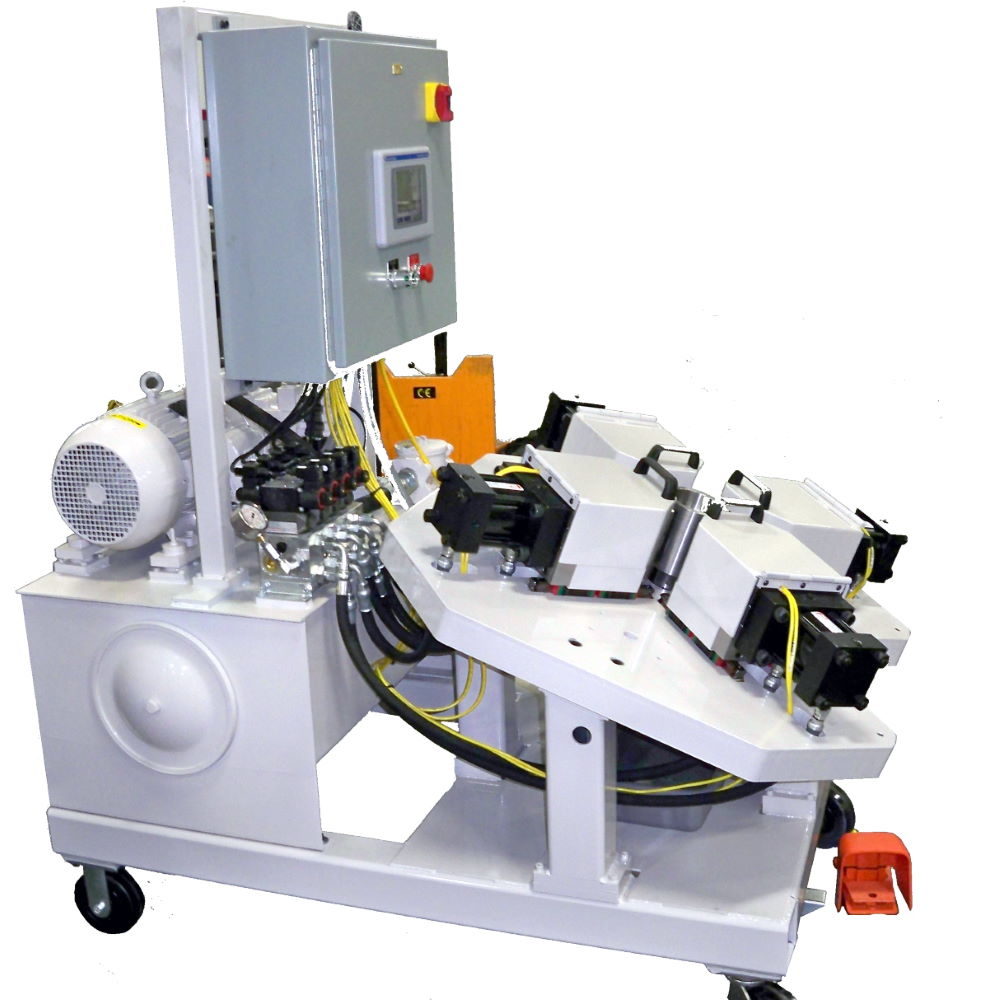

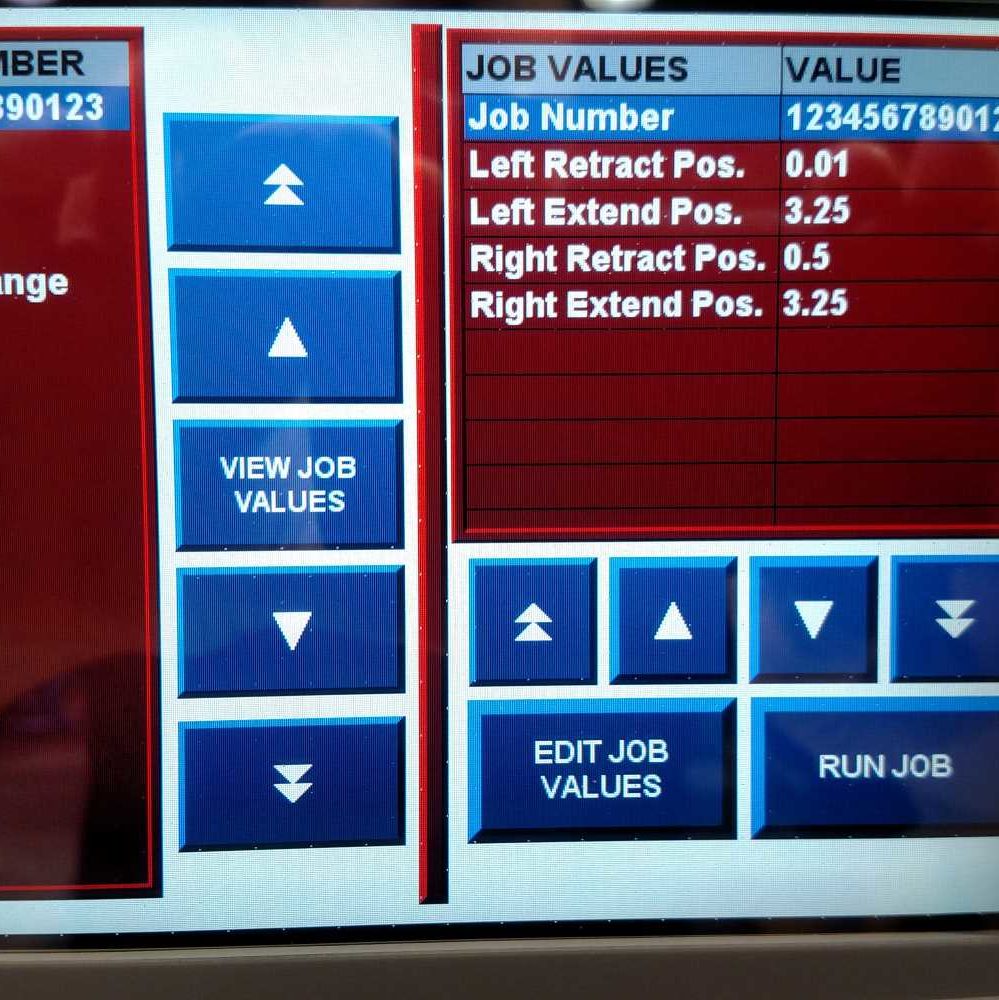

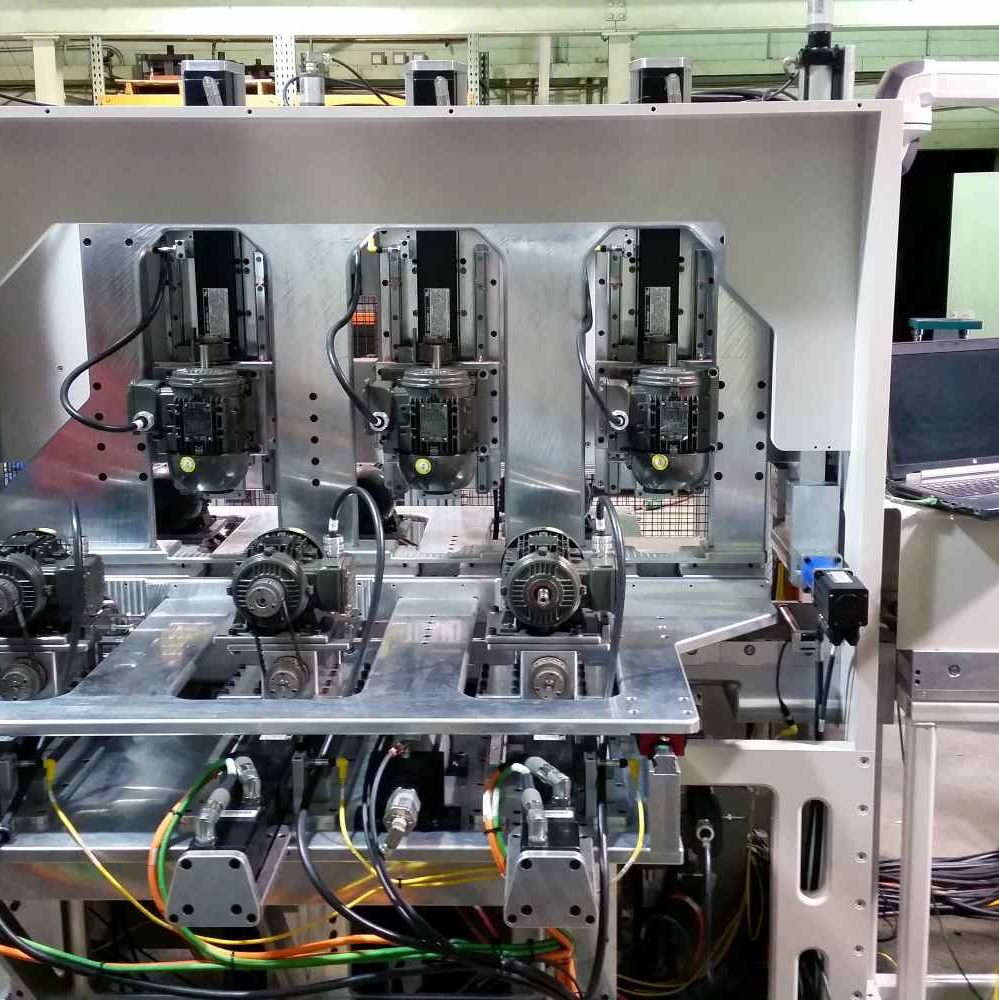

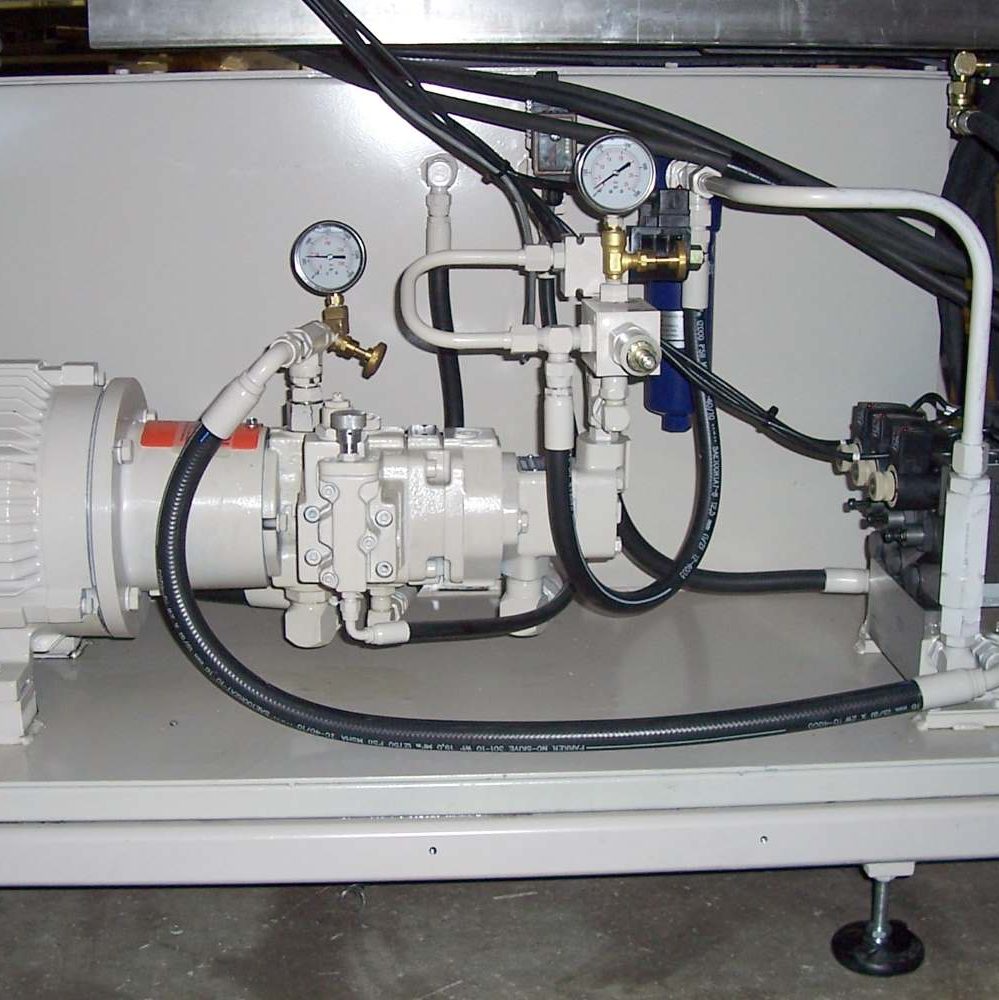

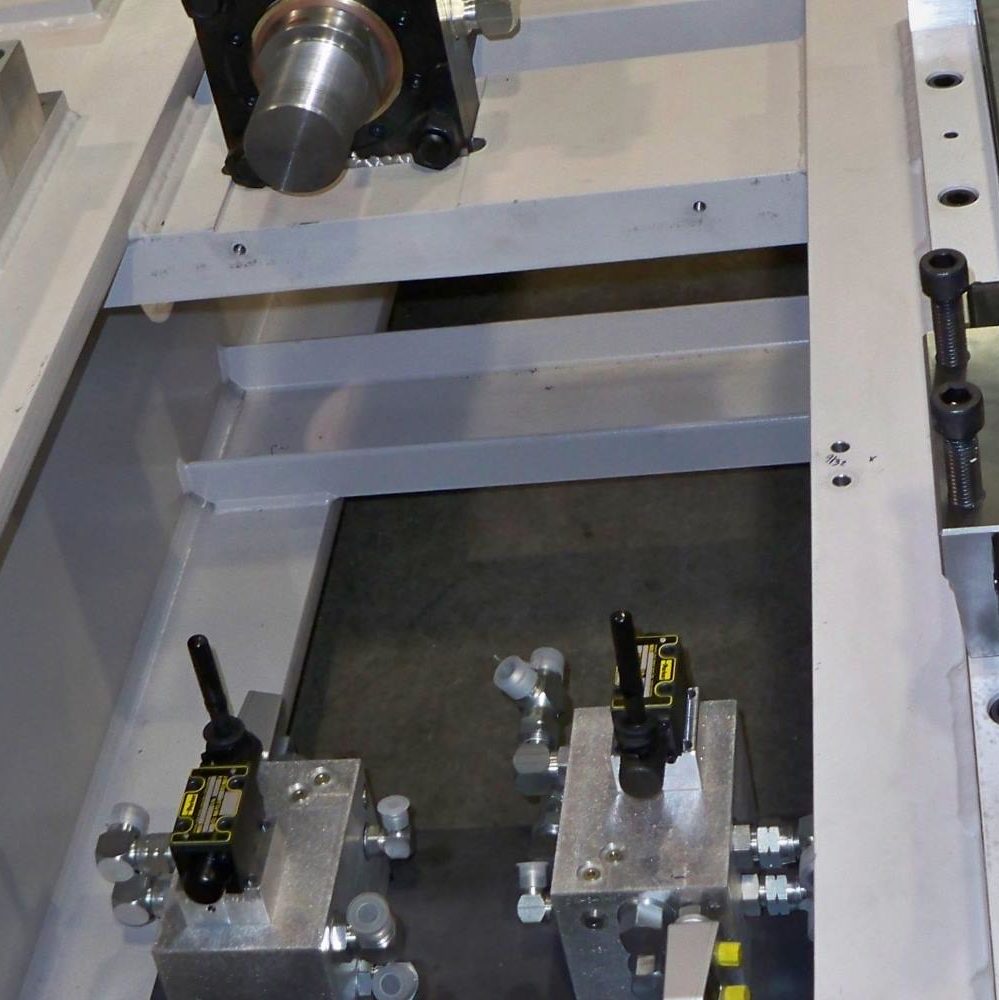

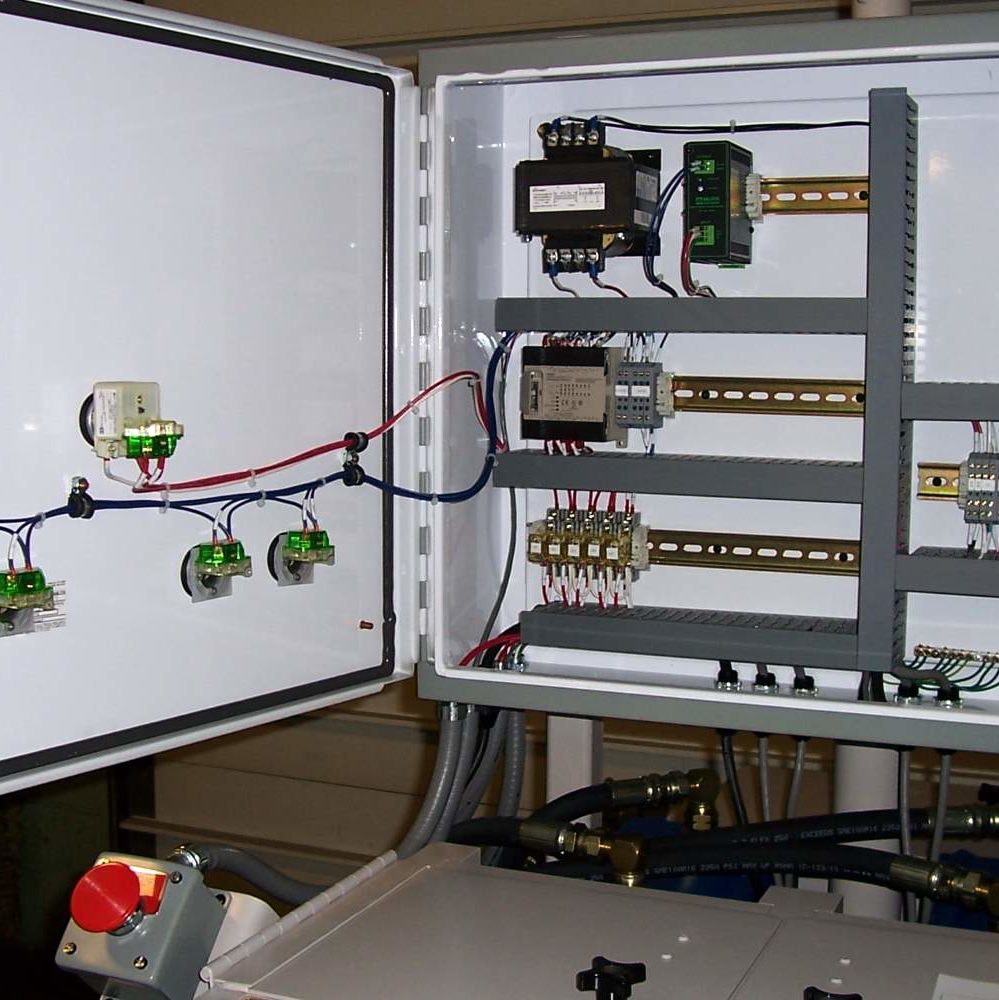

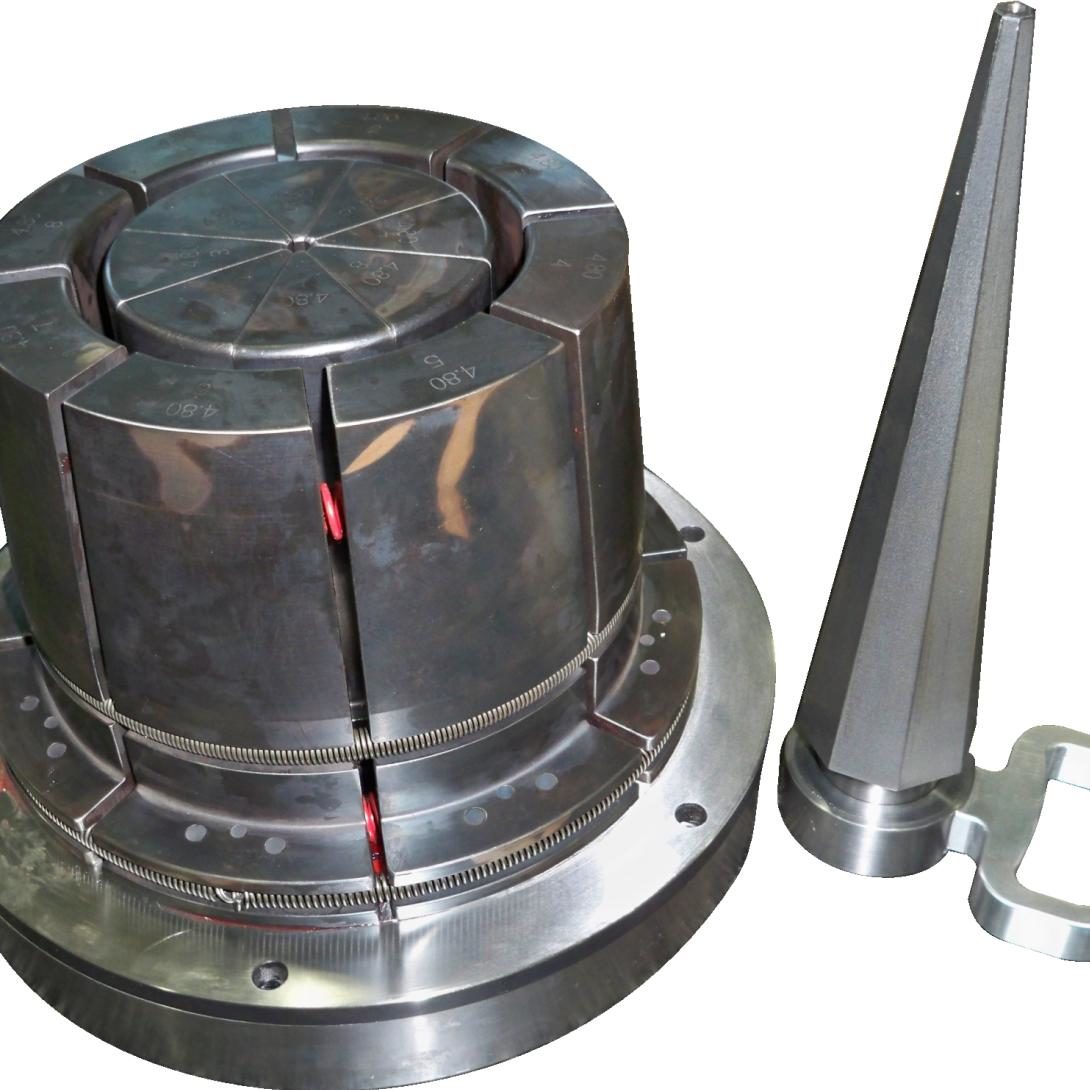

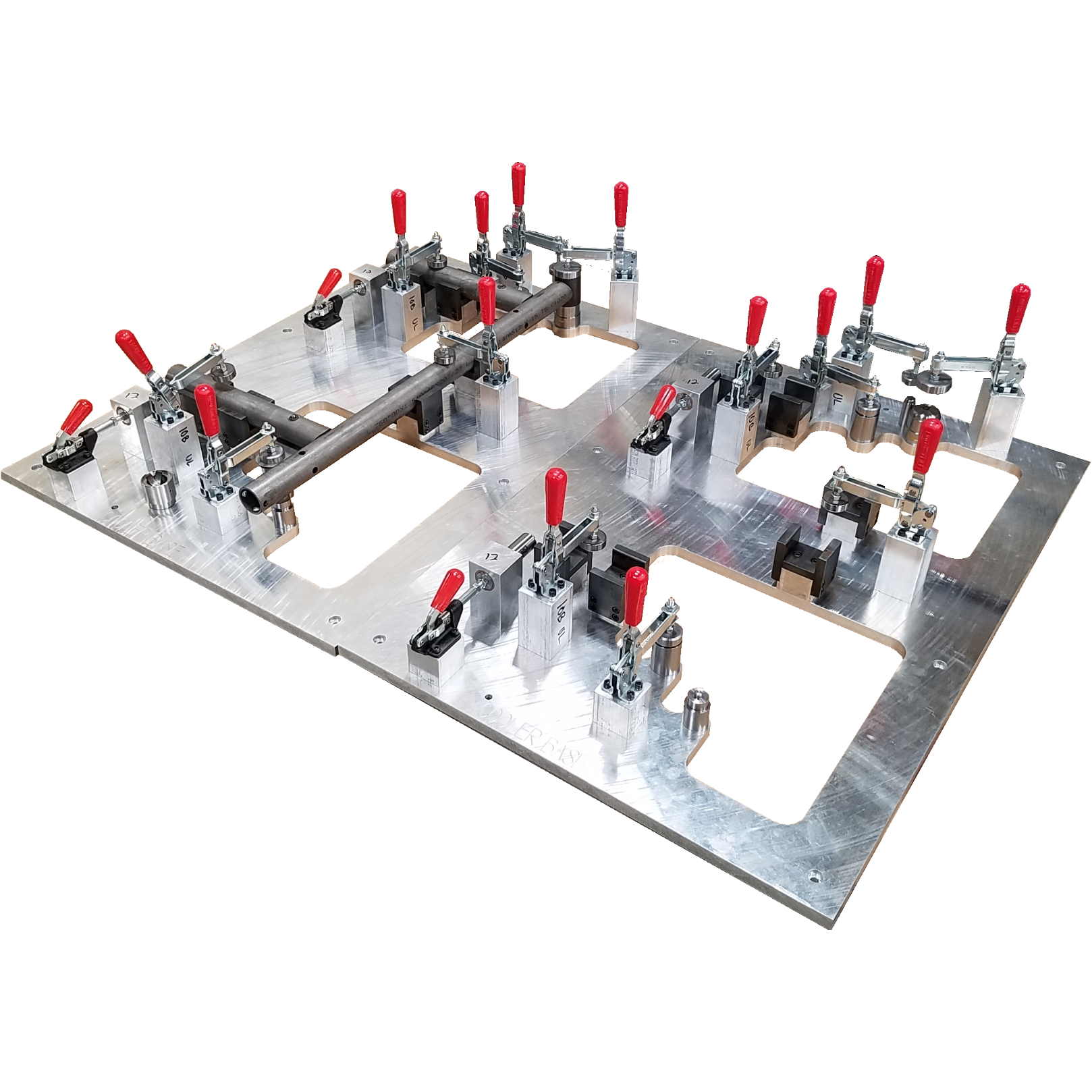

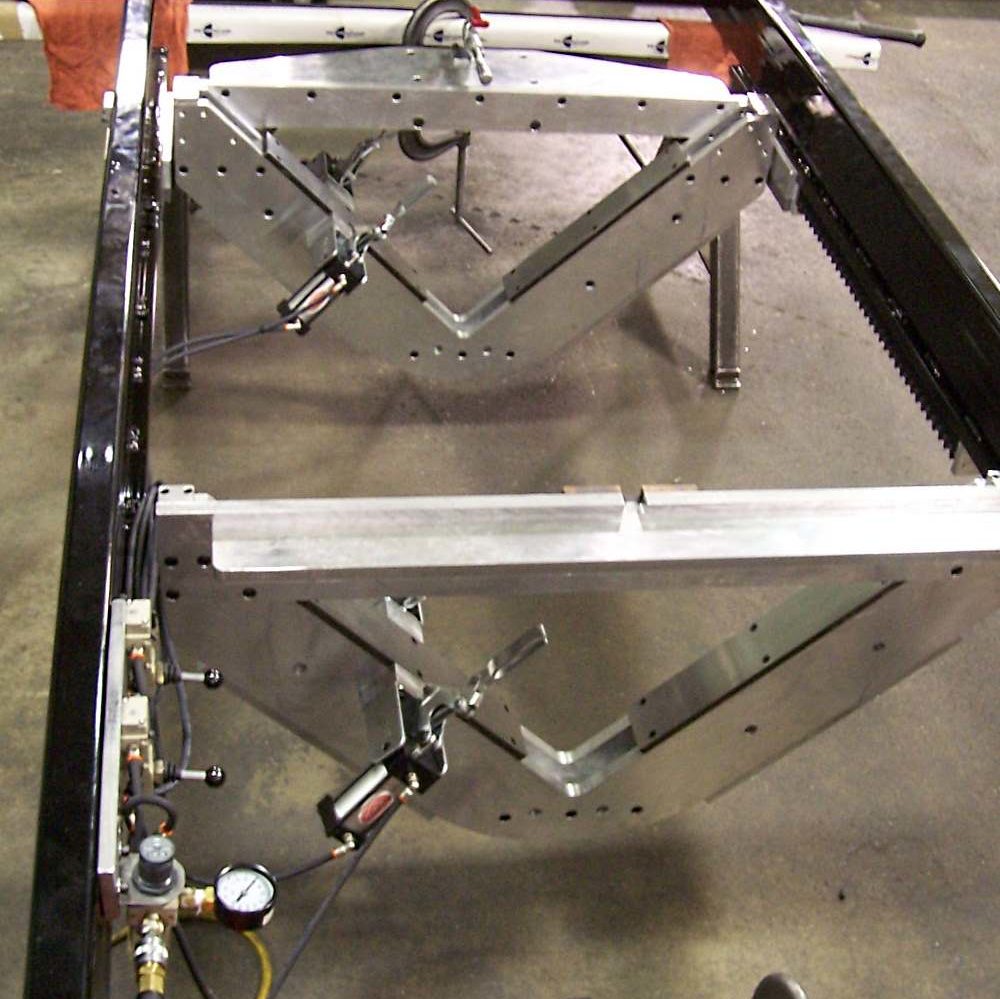

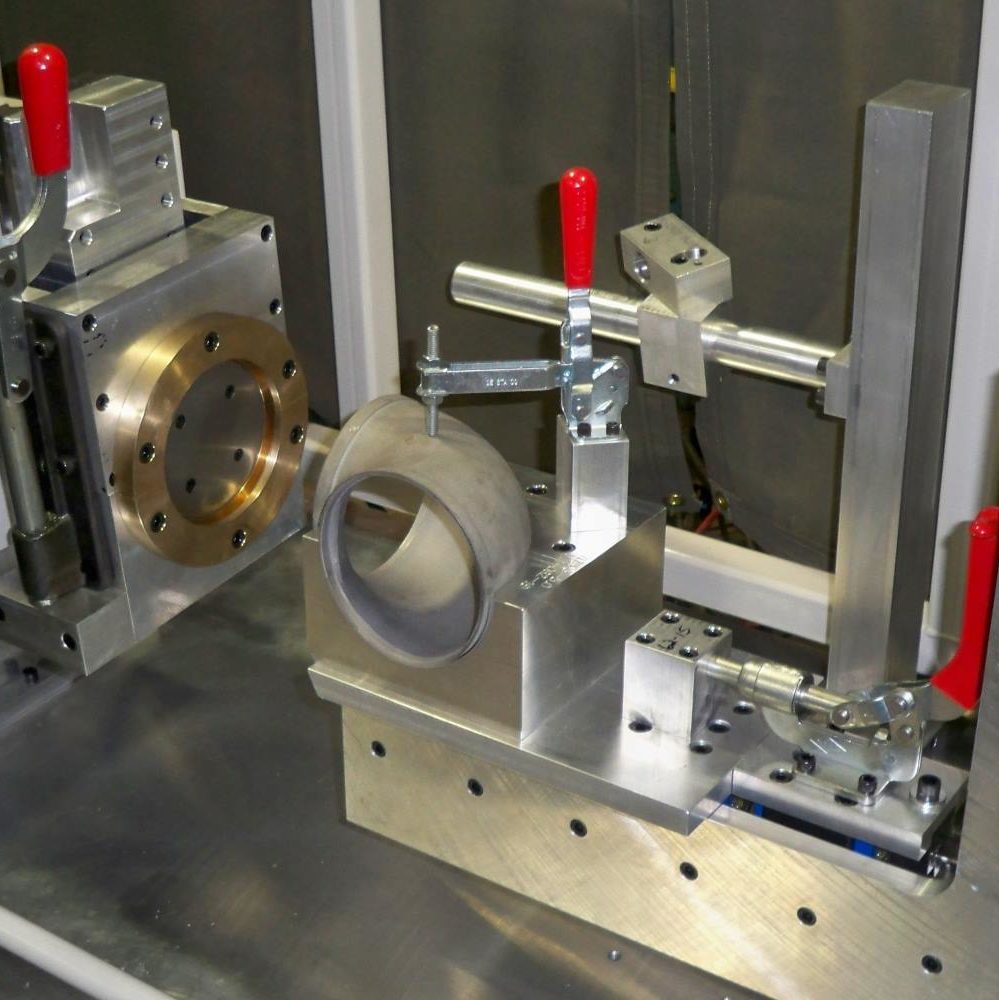

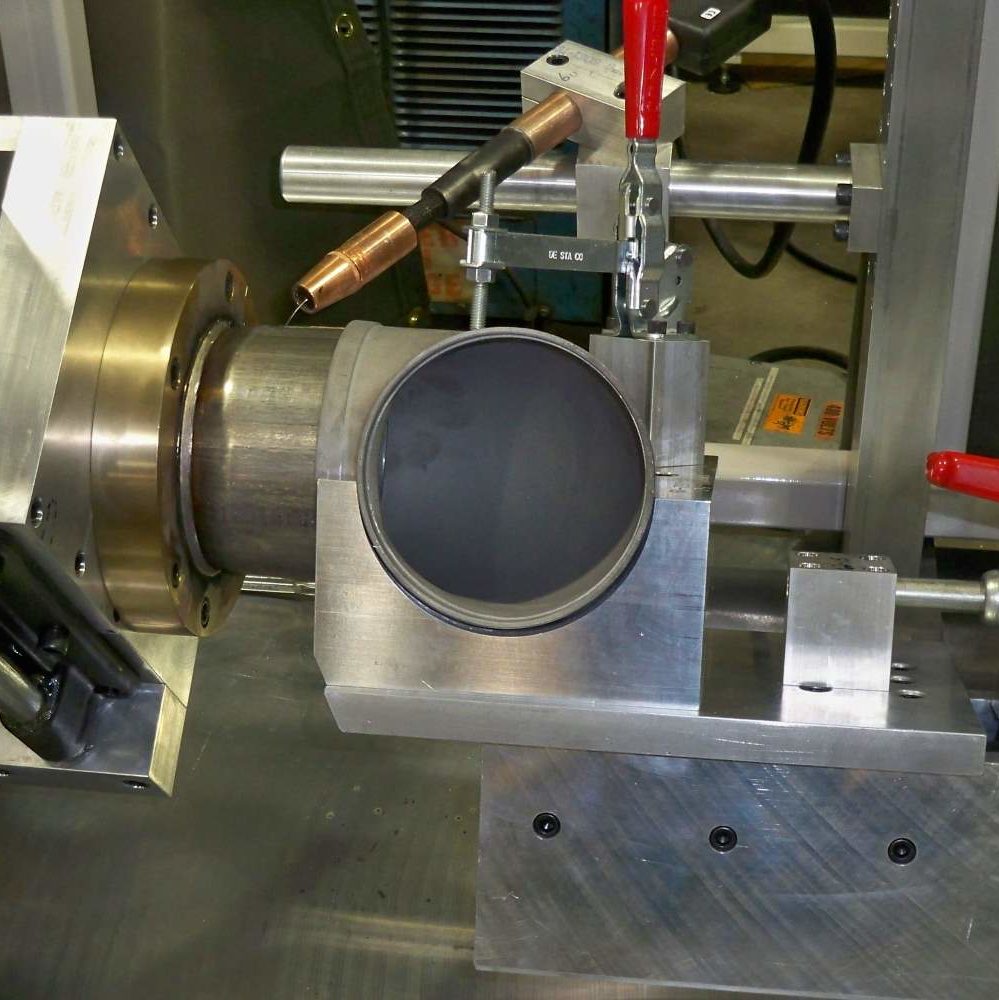

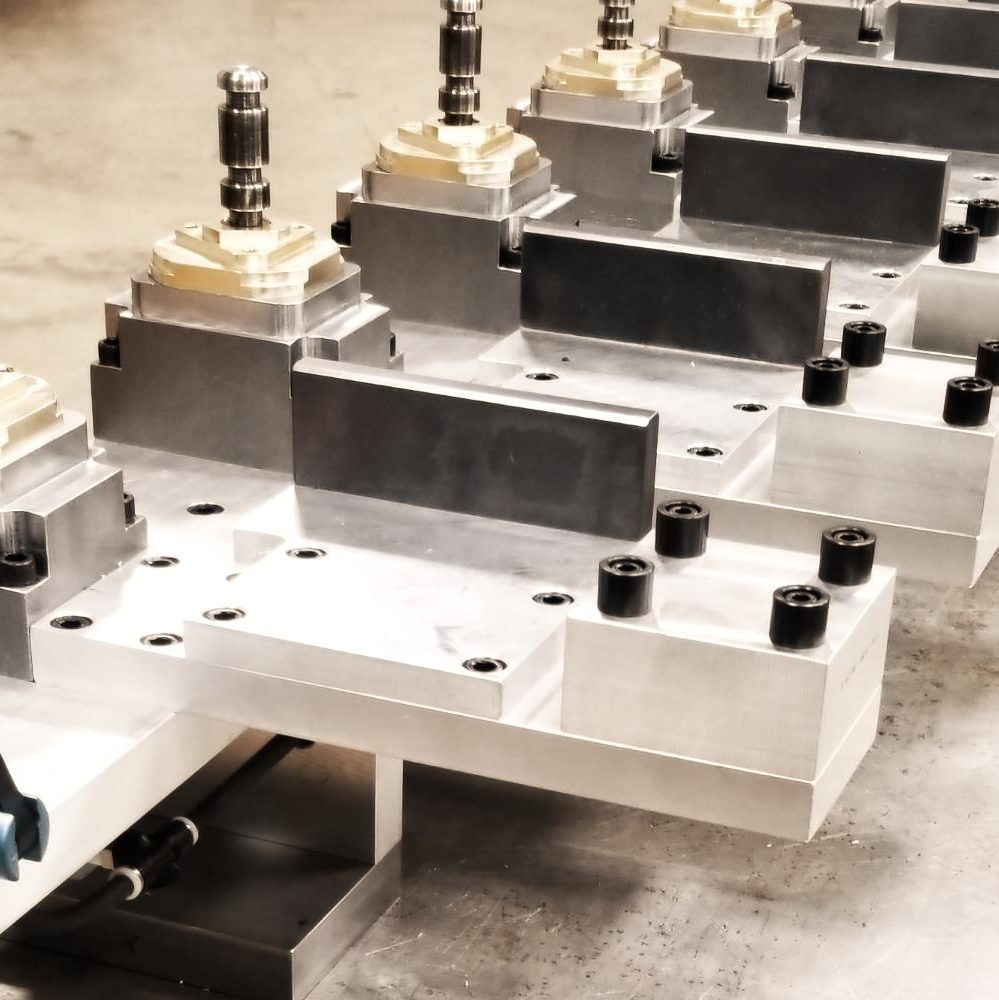

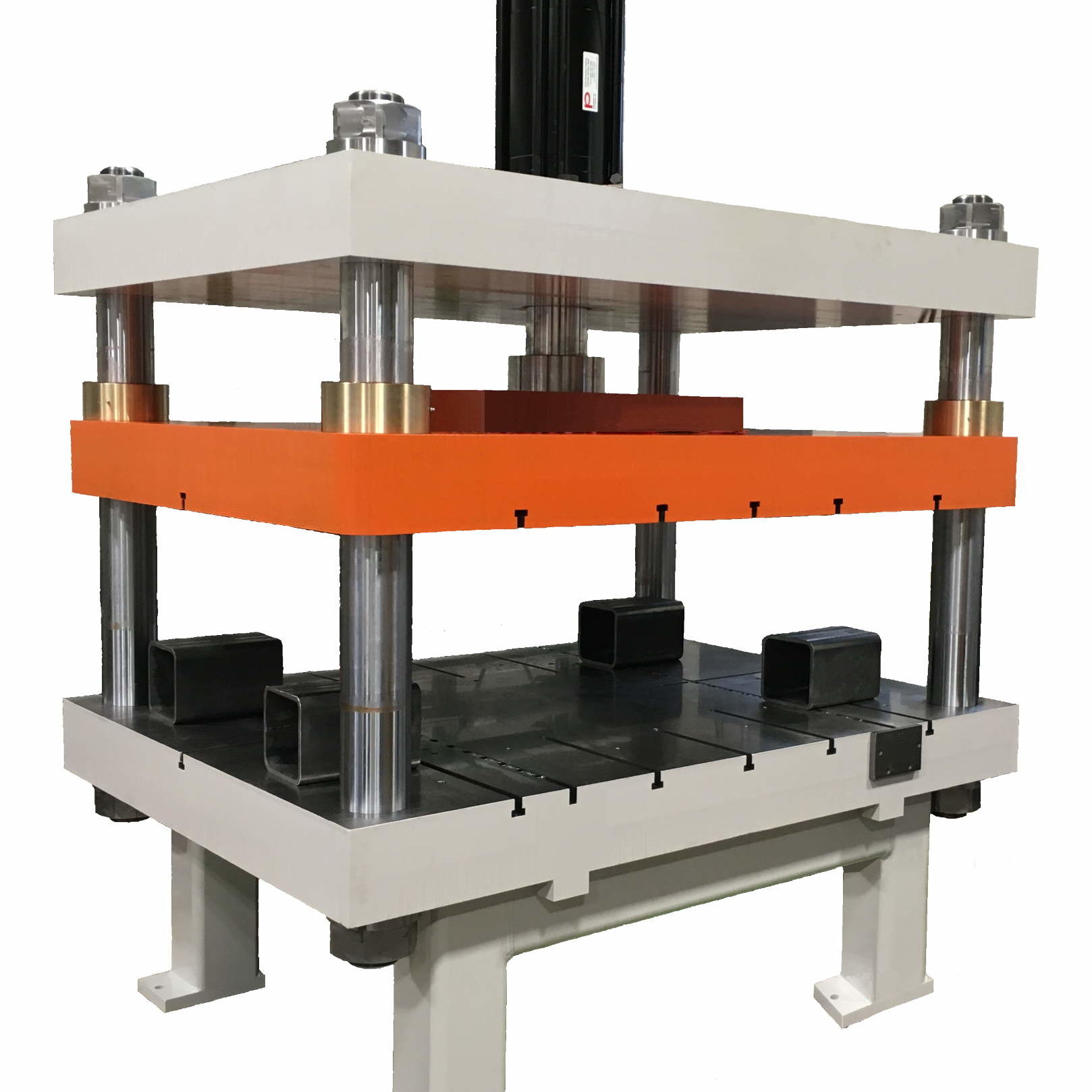

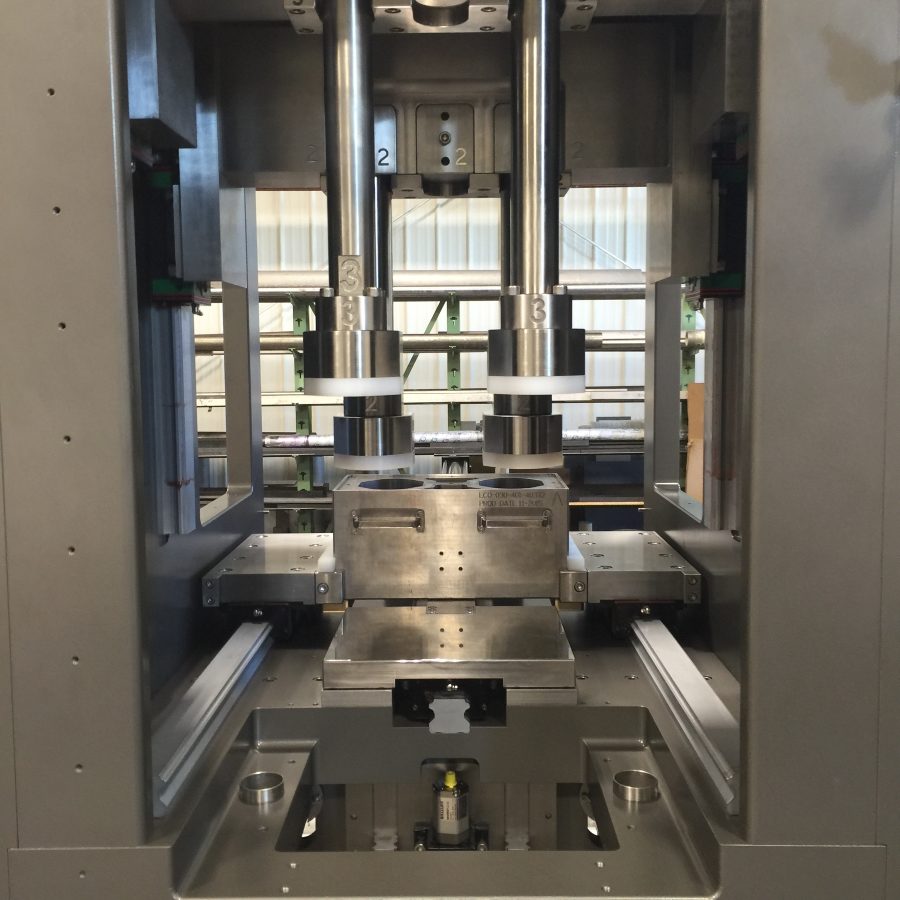

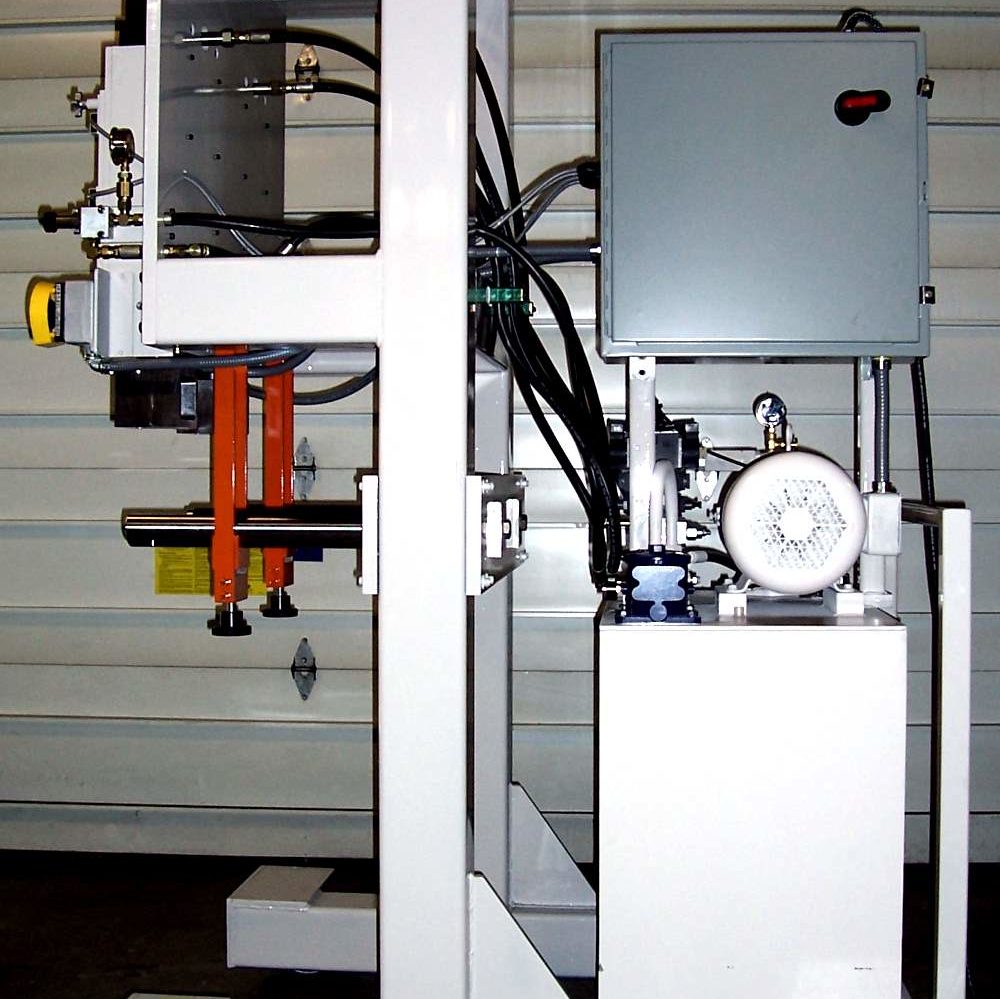

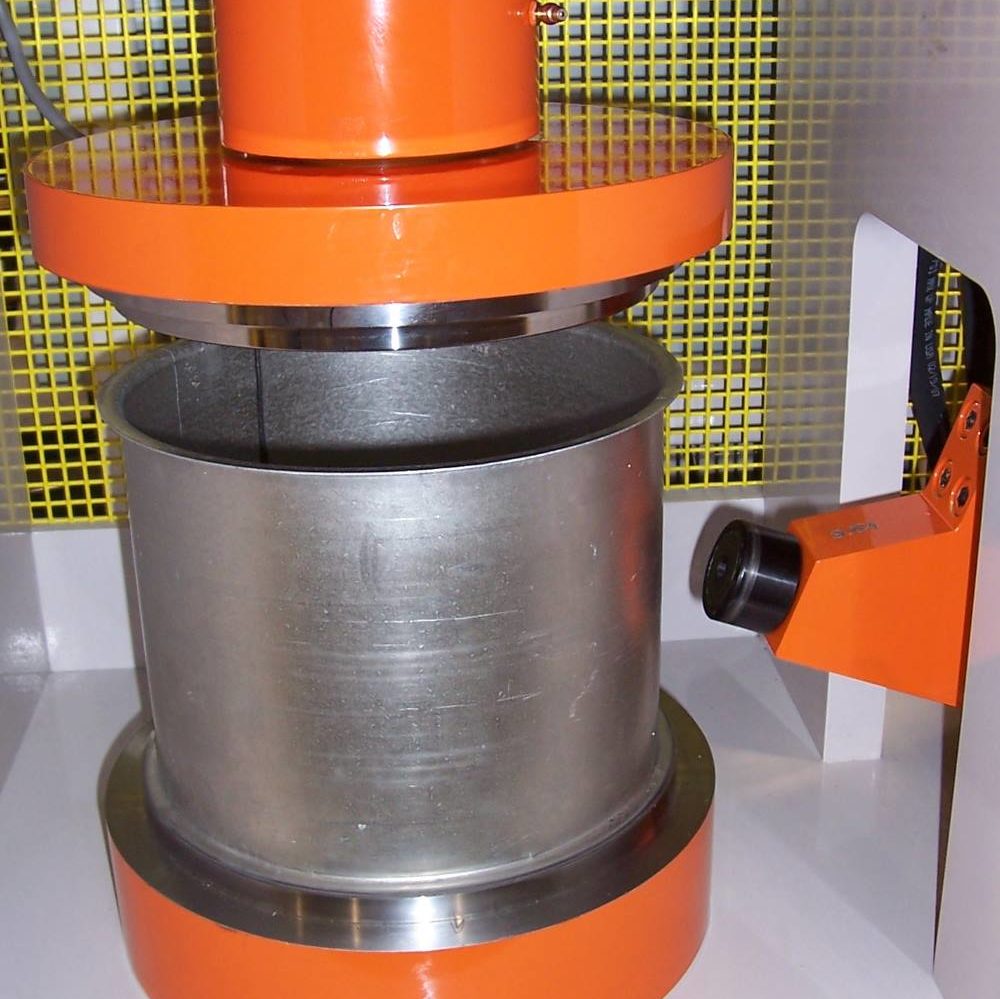

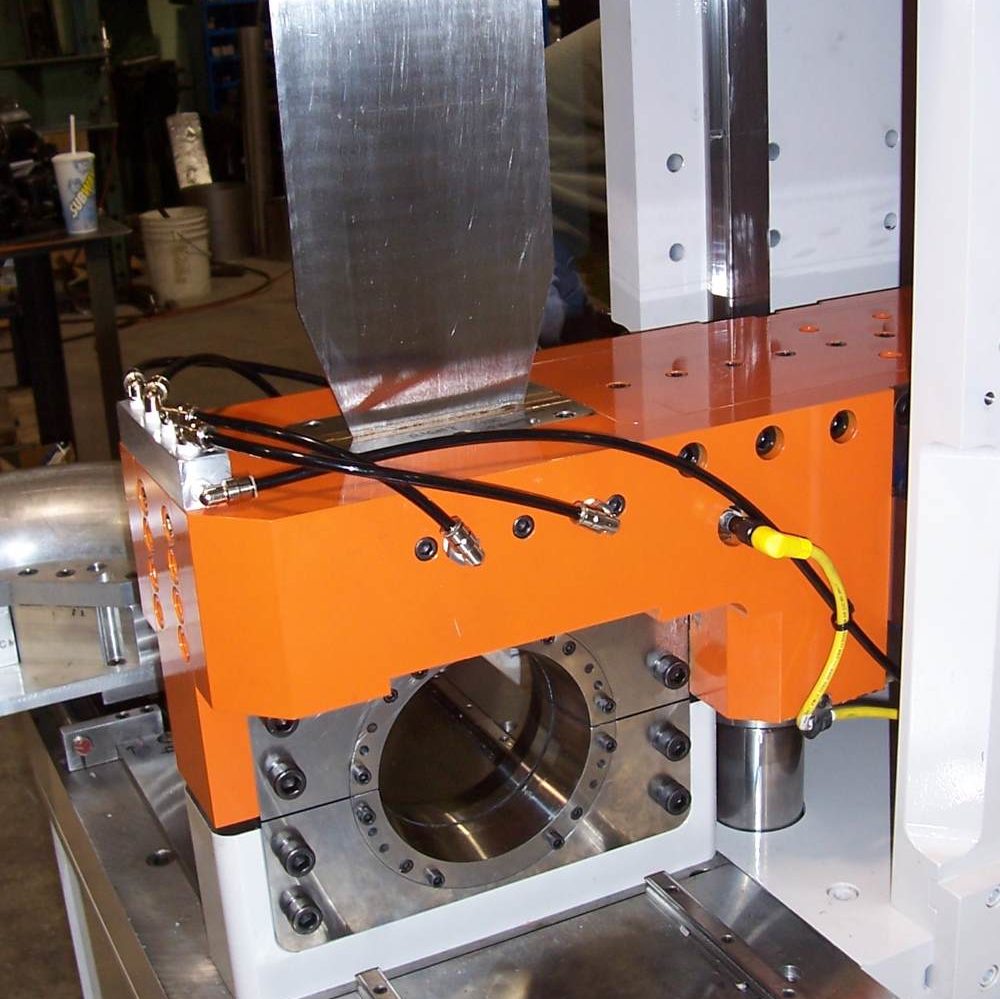

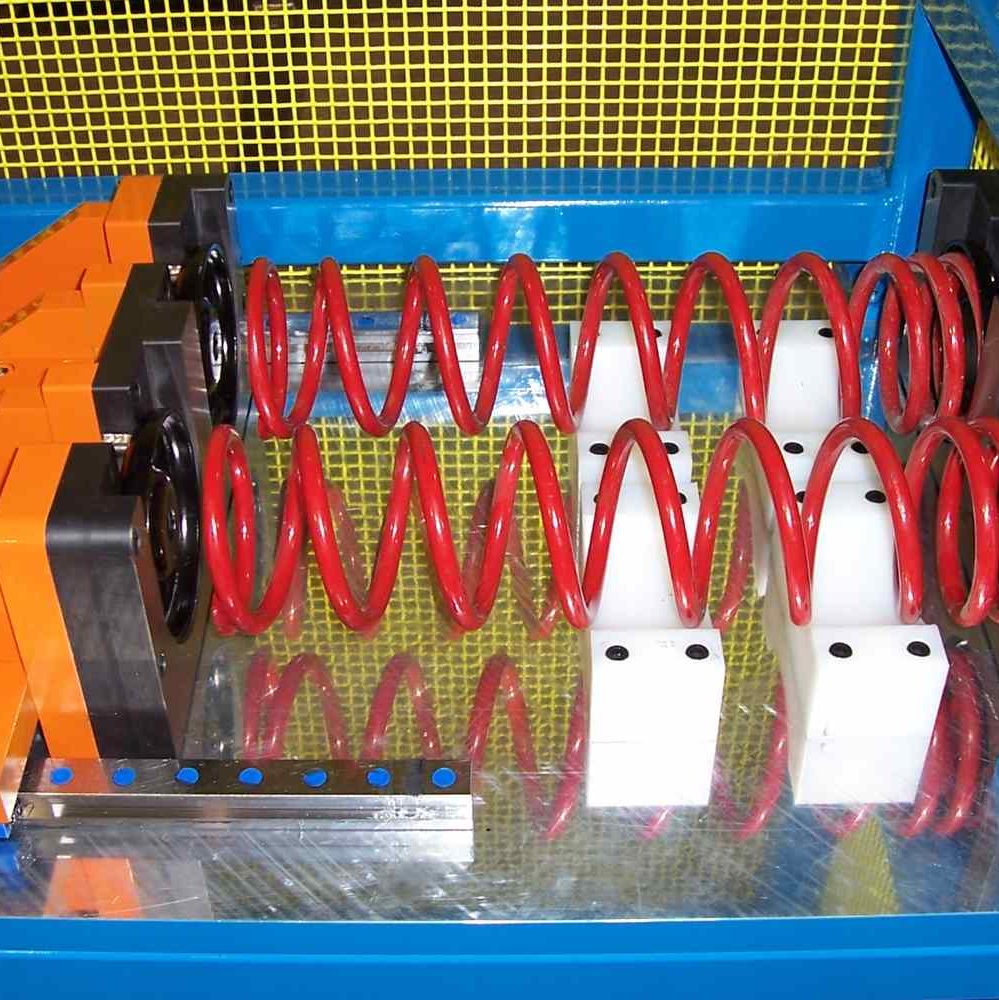

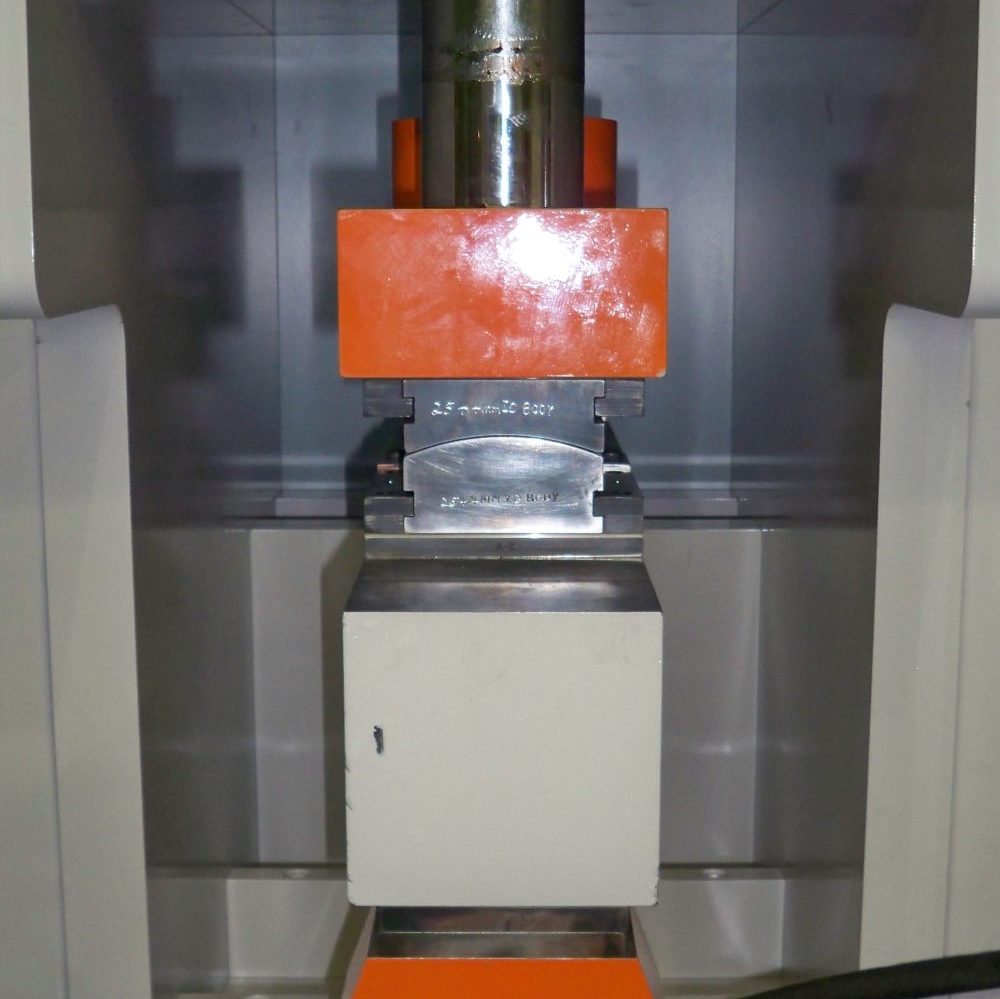

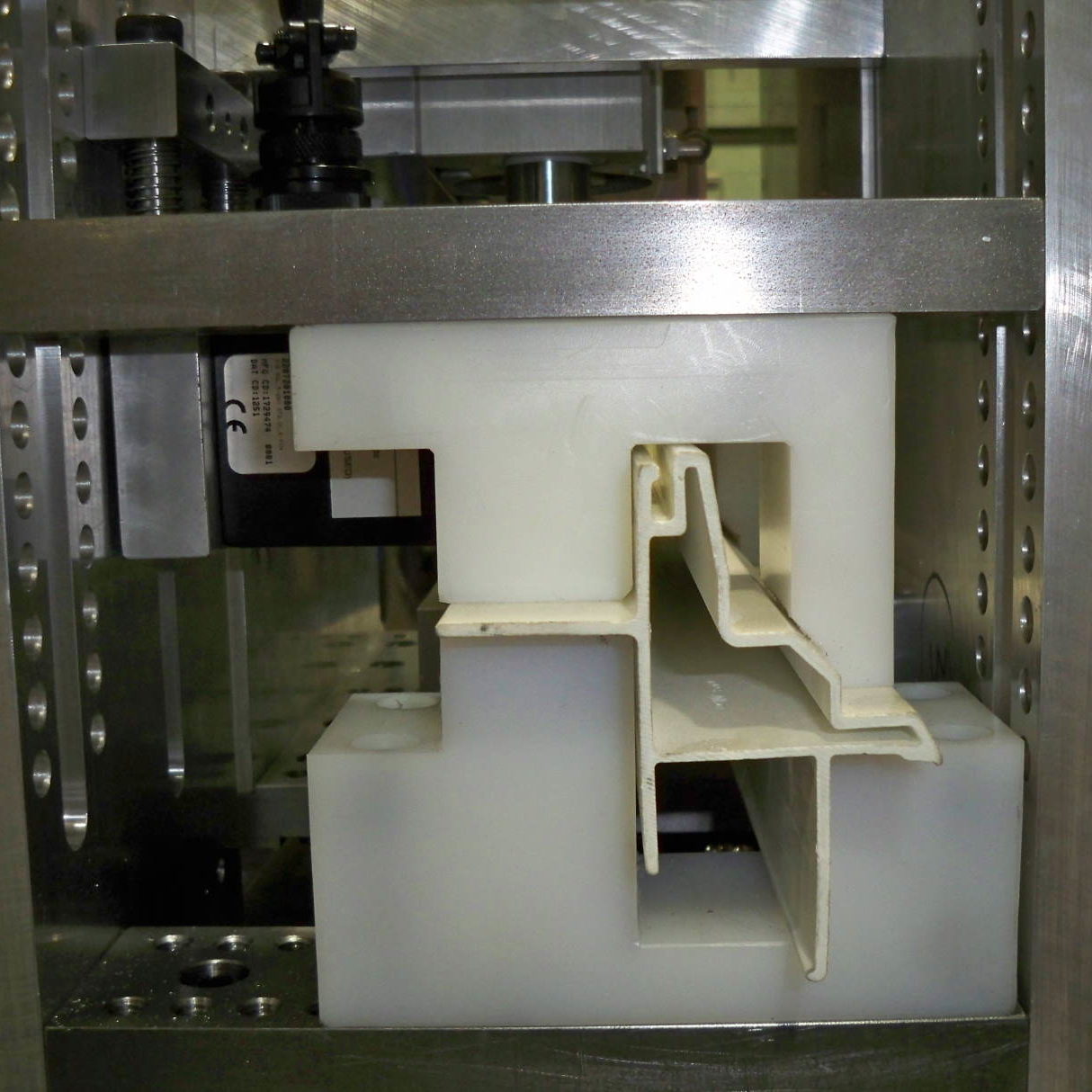

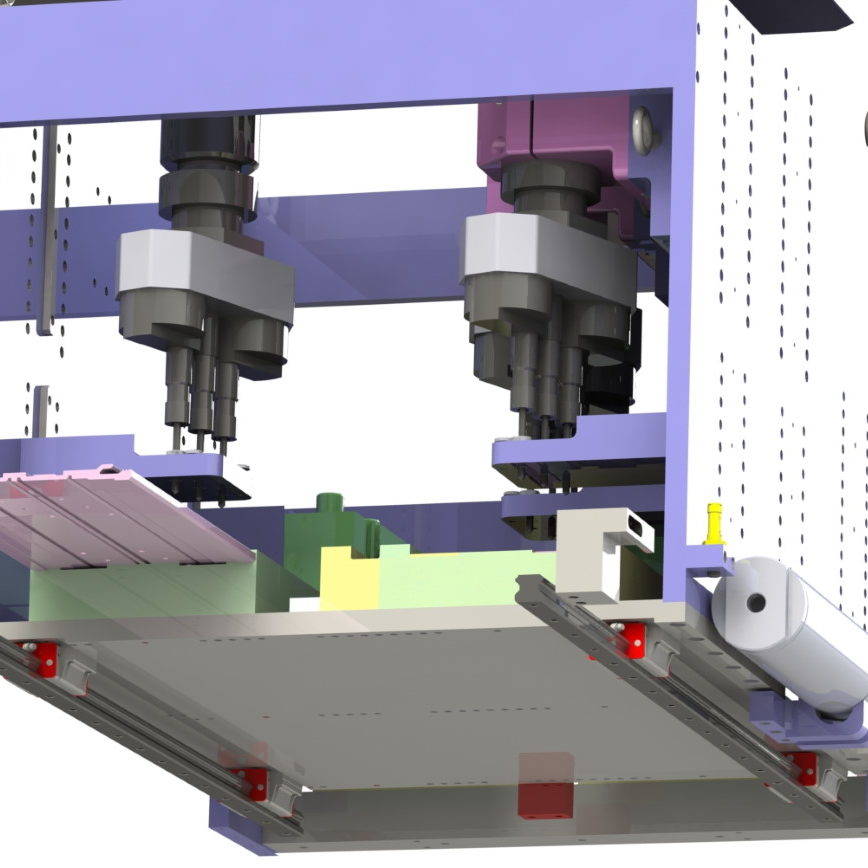

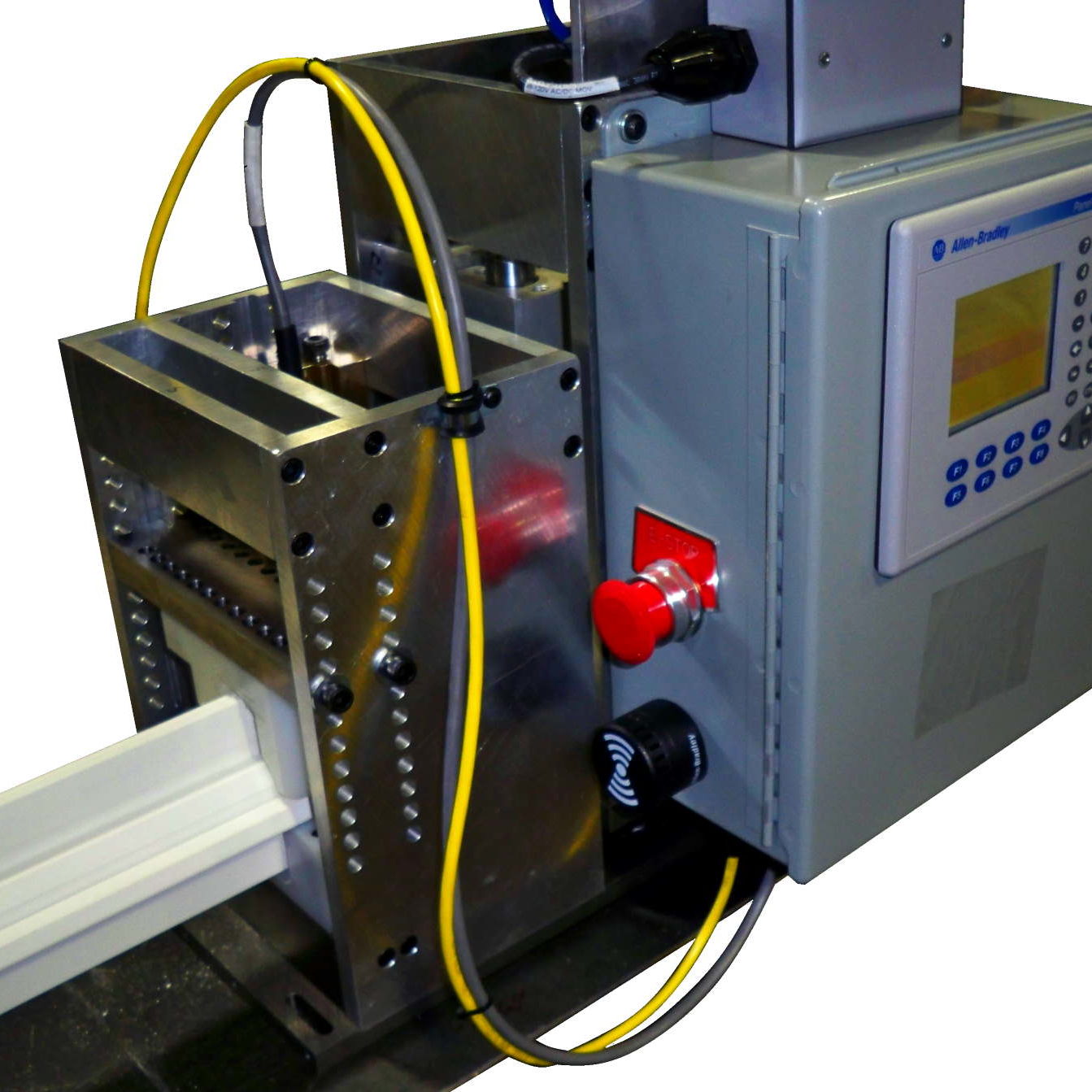

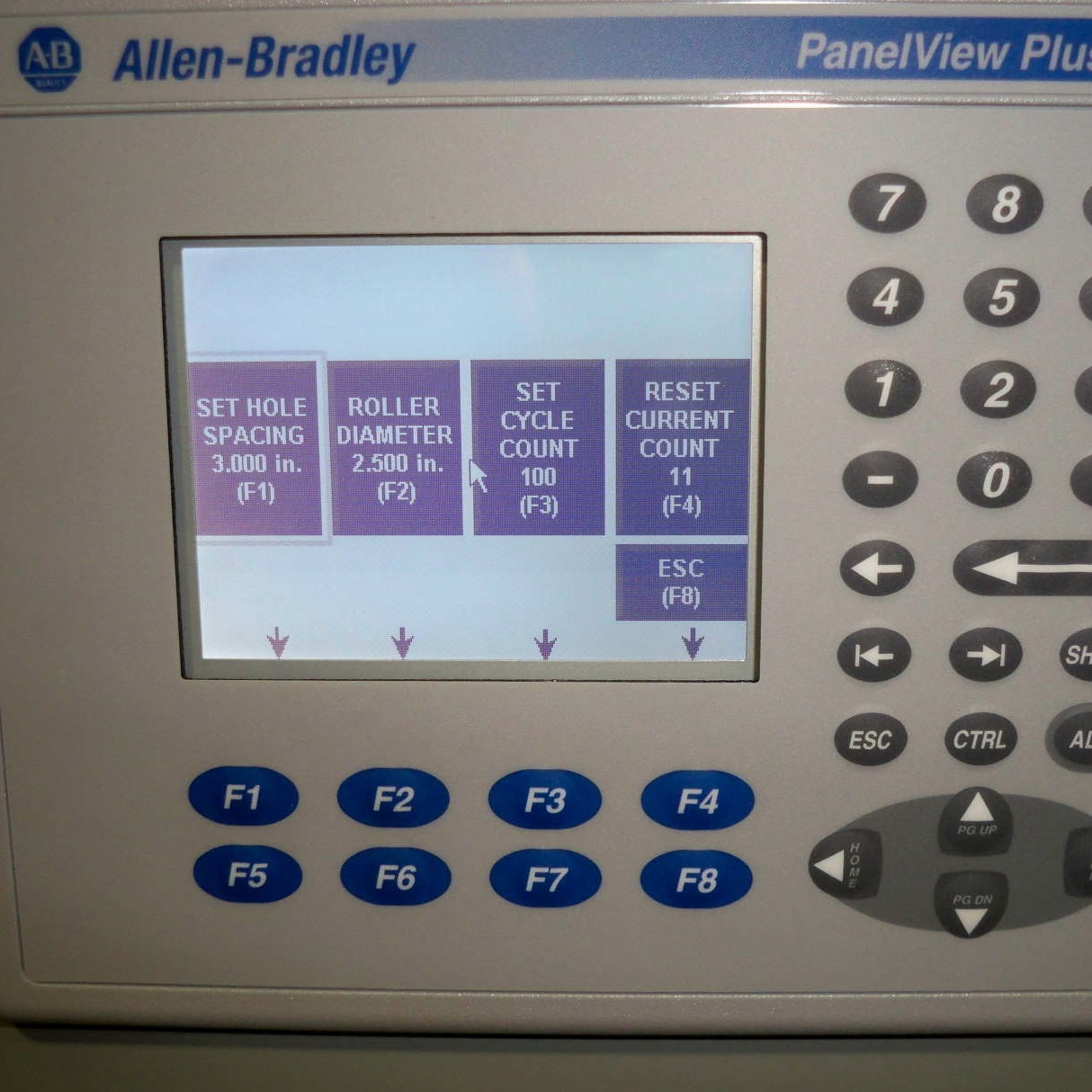

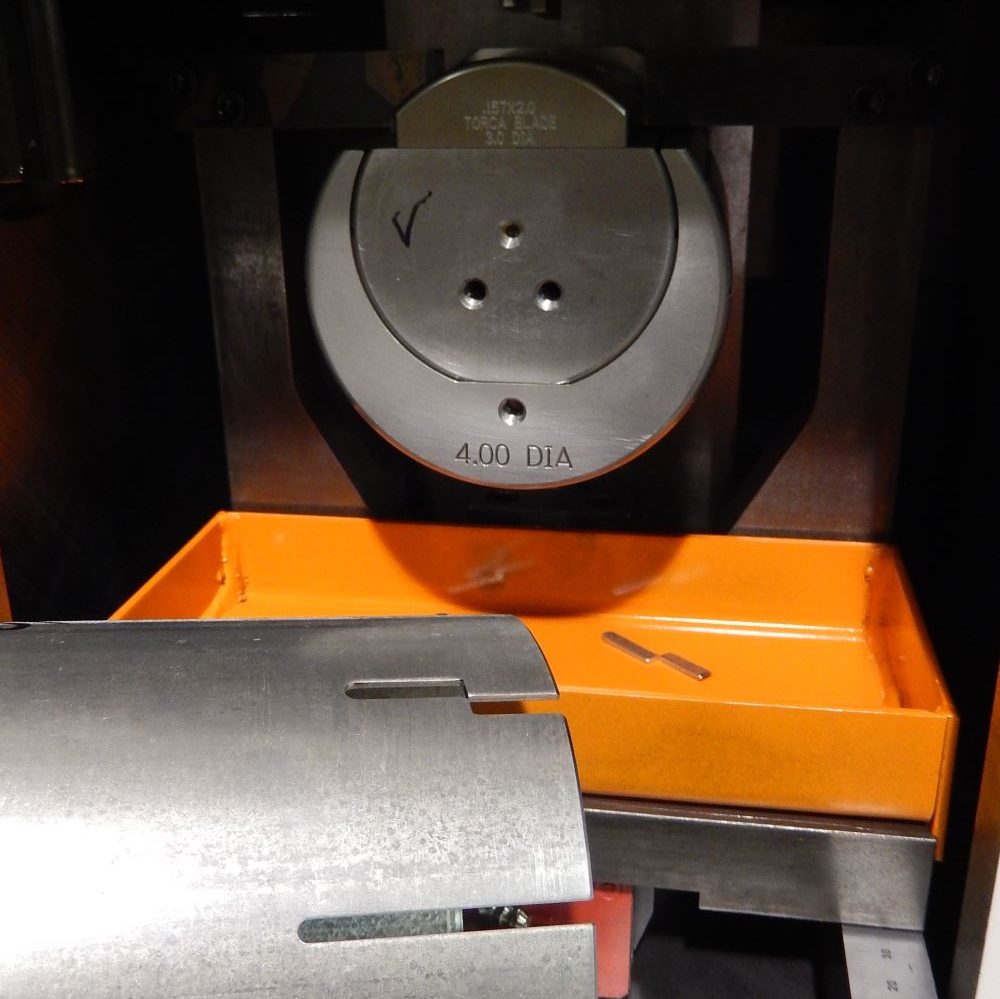

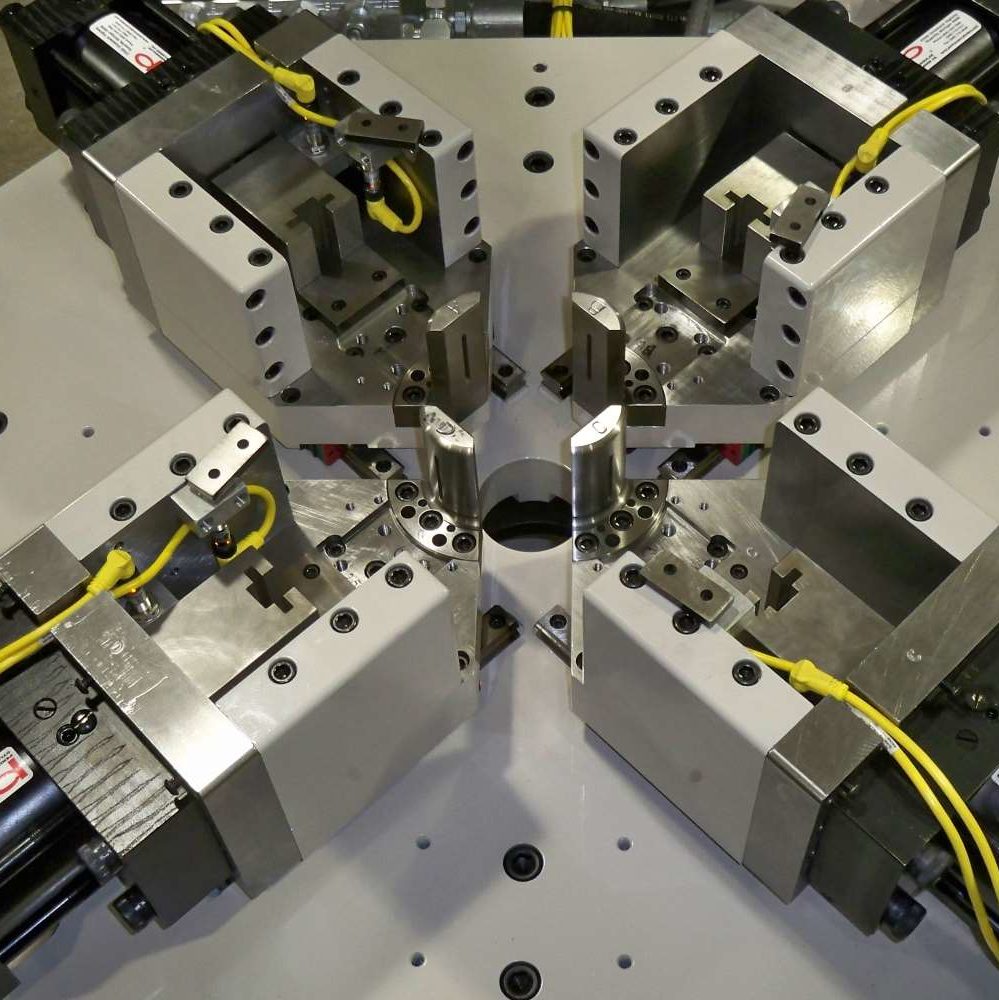

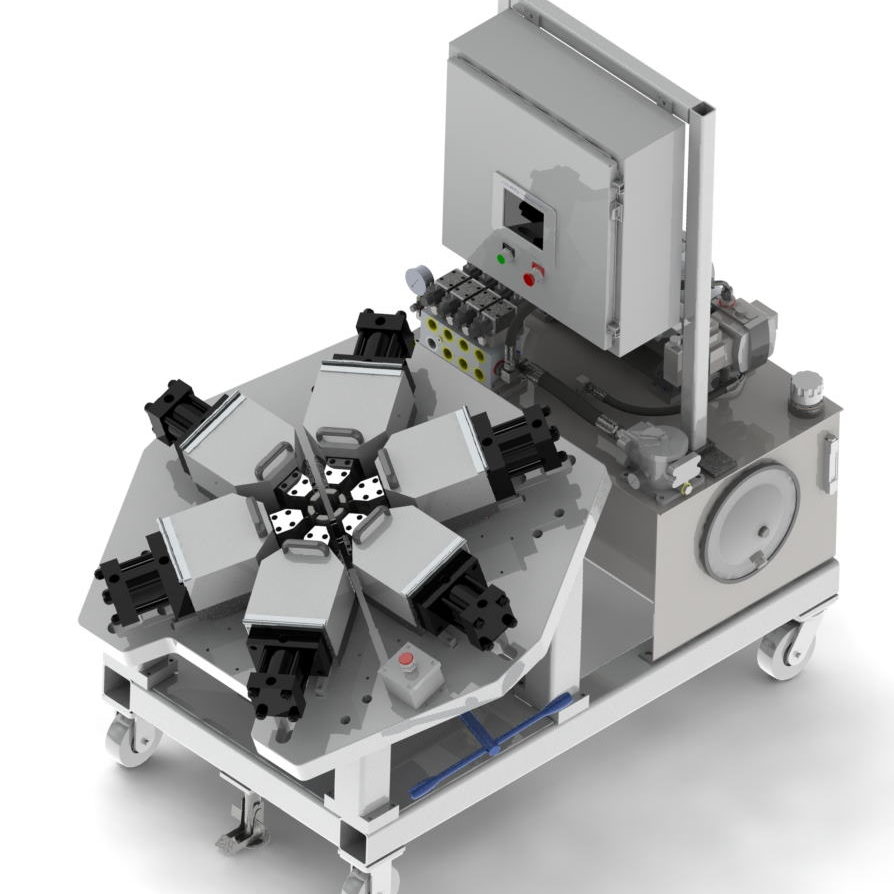

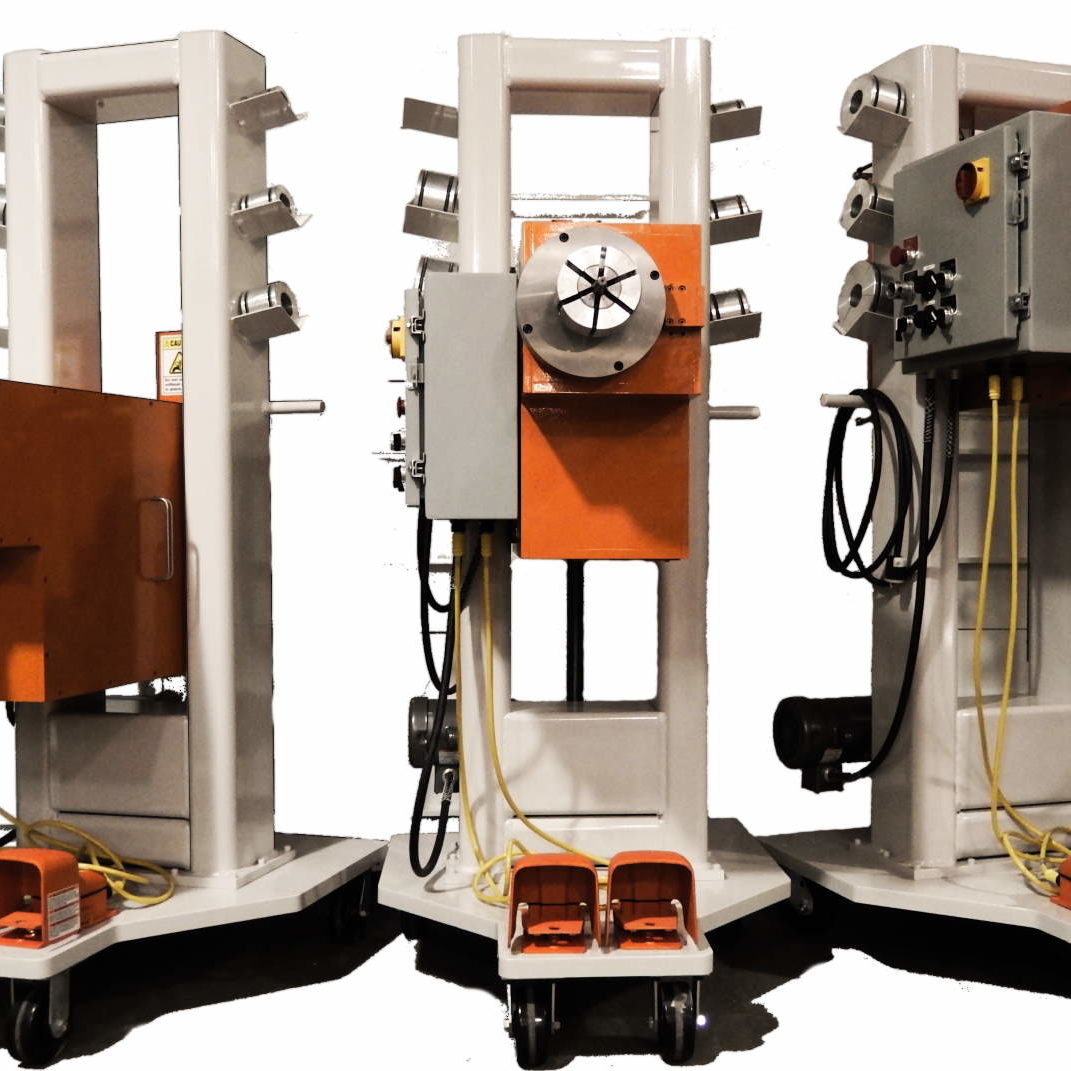

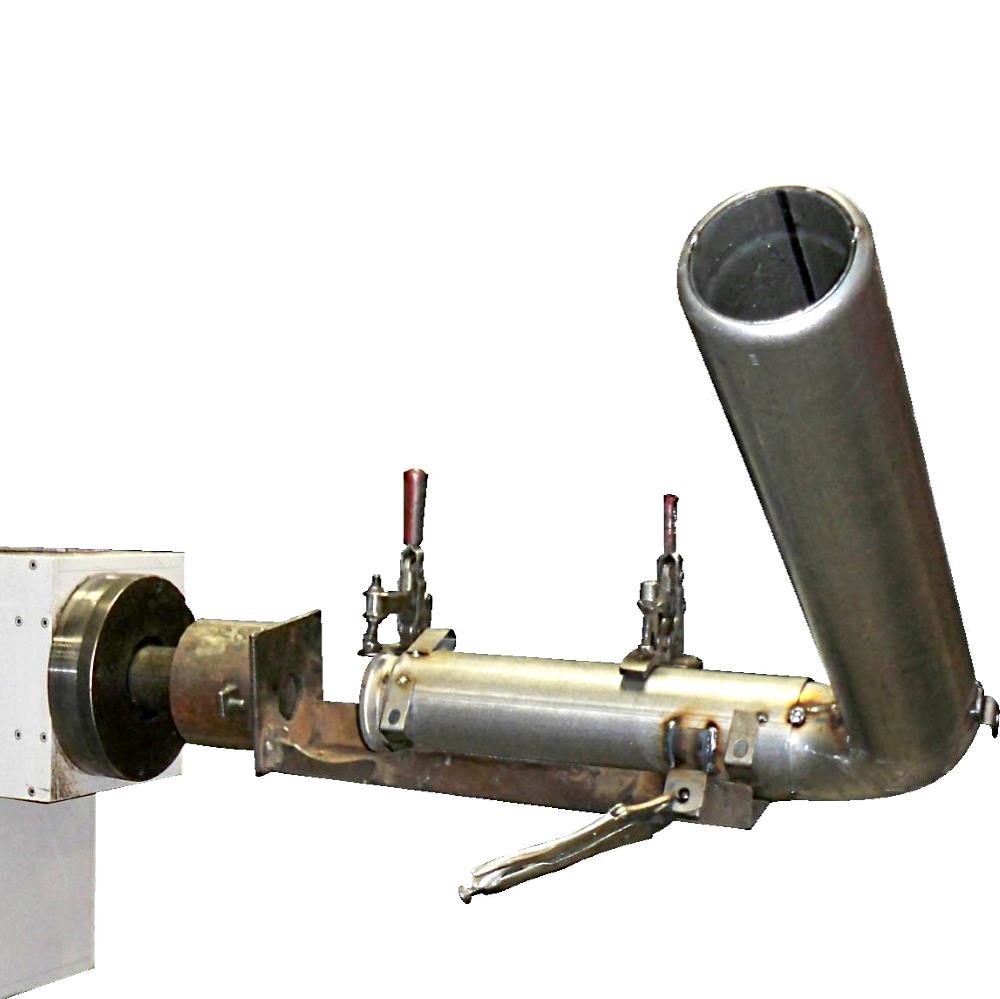

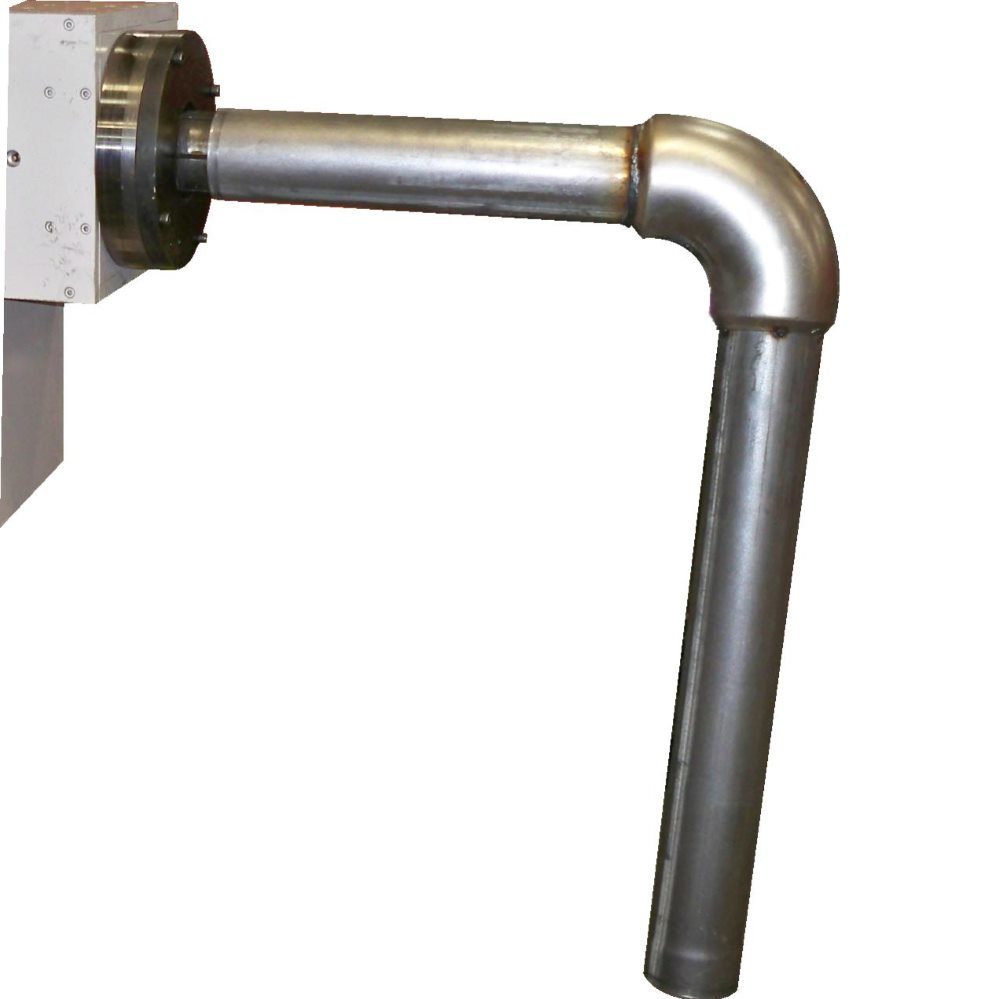

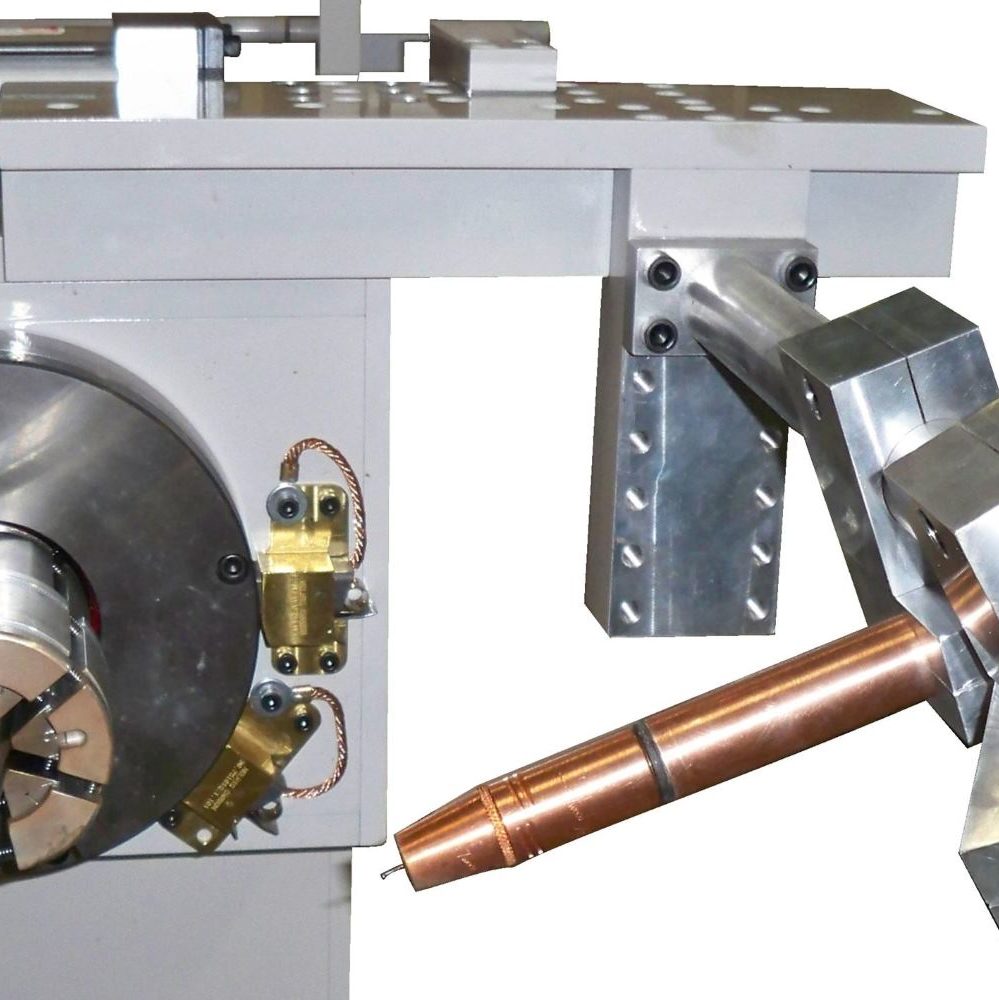

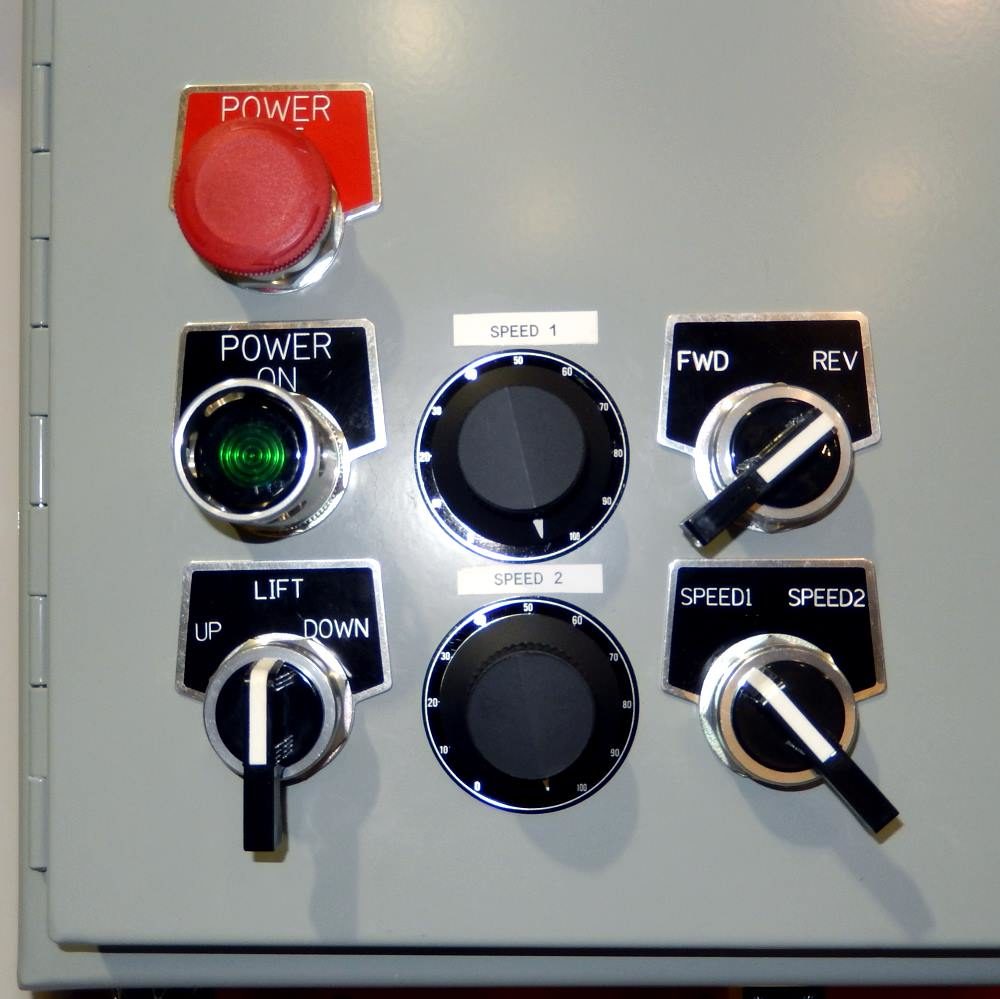

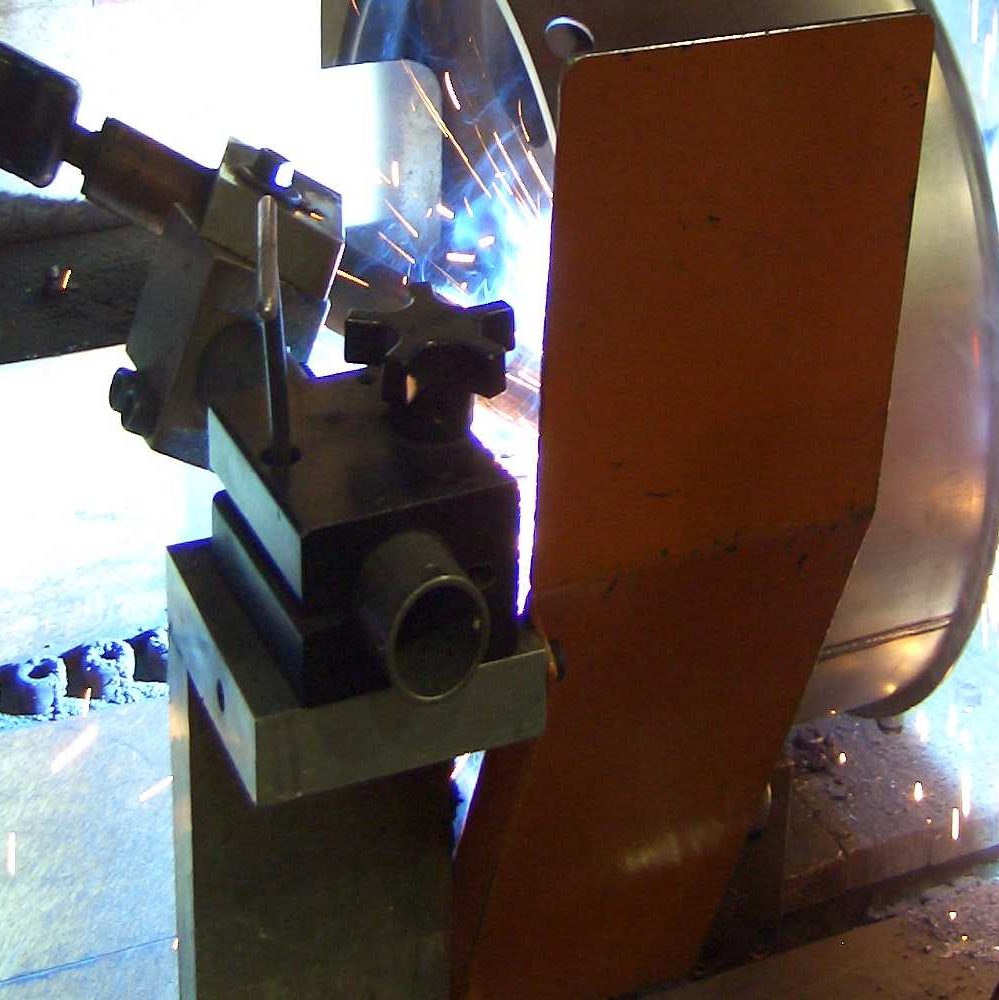

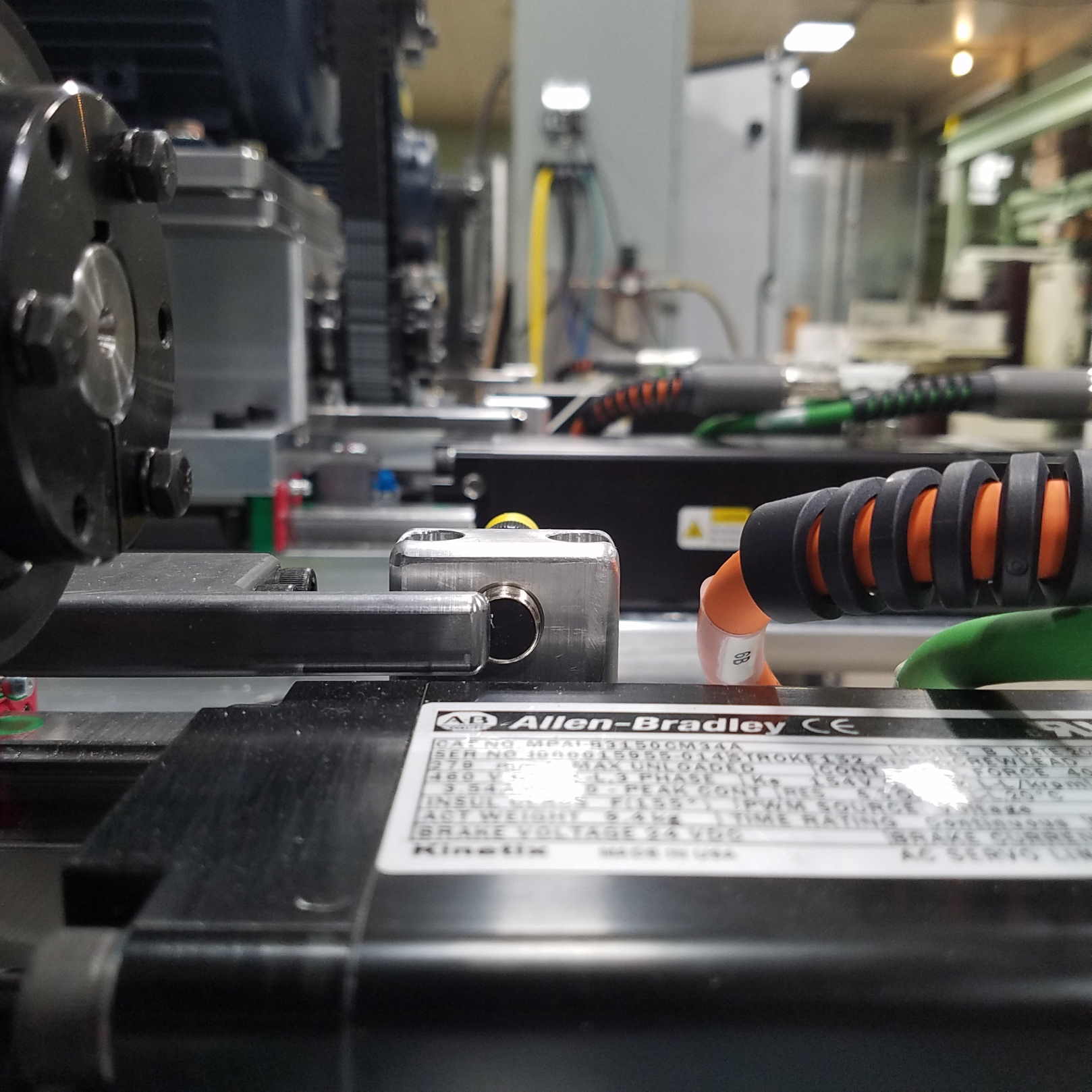

In addition to custom equipment, WSTD has a lineup of standardized machines for a variety of tube operations. These include end sizing, slotting, work-holding and welding.

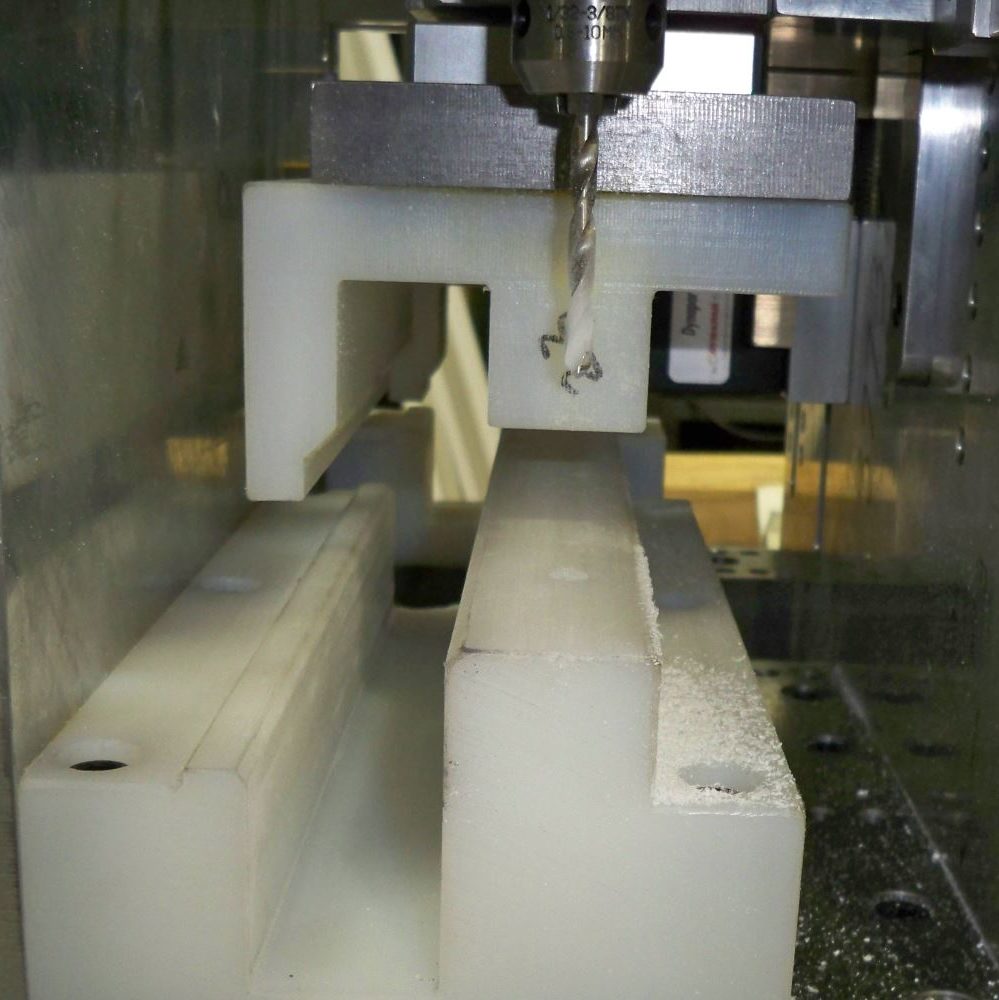

The purpose of this website is to give potential customers a sense for our products. If you have a job that needs thoughtful engineering, intricate machining, or extensive design collaboration, WSTD is the best in the region. Head over to the contact page and get in touch, we should reply shortly.

History

In 1974 West Salem Tool & Die started as a small shop specializing in industrial tooling, dies, and fixtures. Wisconsin tool and die companies had ups and downs as the automotive industry in Detroit went through its boom and bust. Of those companies, many don’t exist now. However, we survived and grew, and don’t plan on going anywhere. So you can rely on us to be around for the next job. The company has grown to employ many expert tool and die makers and machinists with decades of experience. Located near La Crosse, WI, the company conveniently occupies several buildings right off I-90.