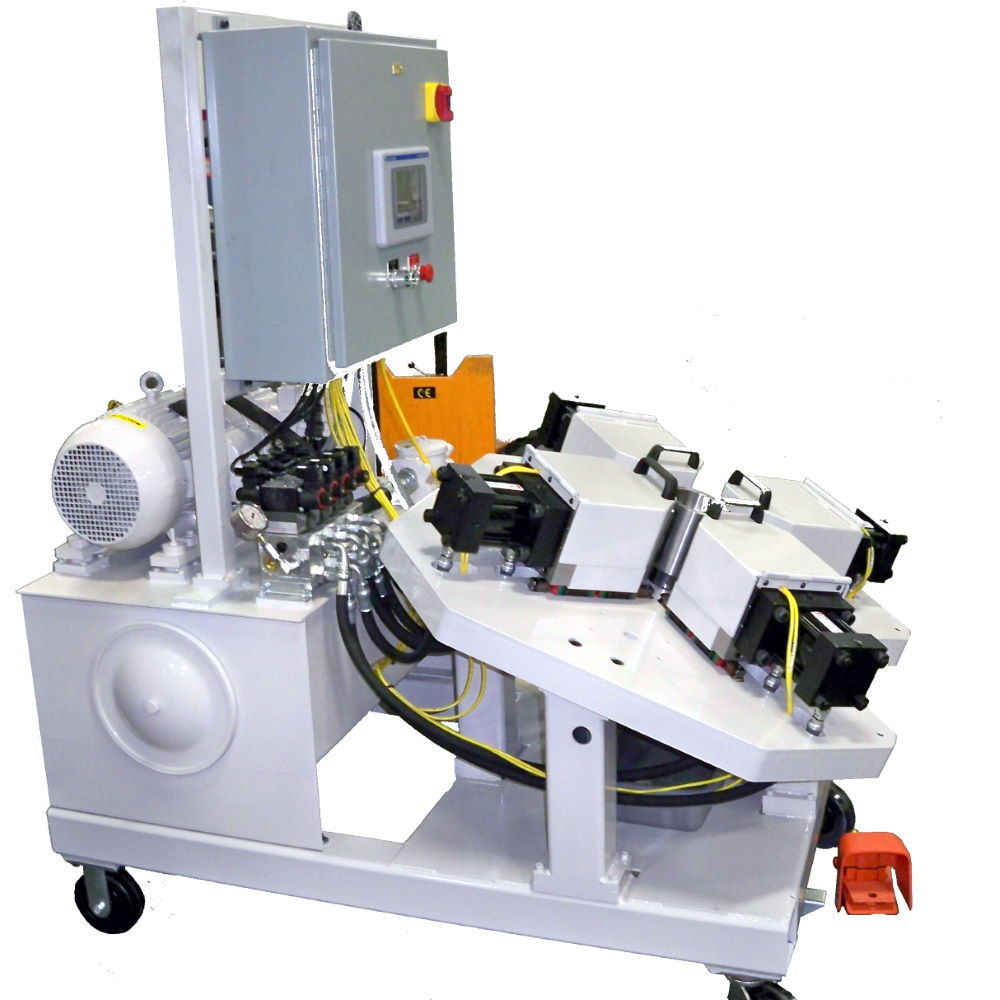

Custom Machines & Systems Integration

West Salem Tool & Die (WSTD) now offers custom machinery design and systems integration services. Our turnkey solutions bring together fluid, electrical, and control systems to meet the unique needs of our customers. Most of our machines end up in American production lines in the automotive, energy, and heavy equipment industries.

The clear advantage of getting a custom-designed machine from WSTD is the ability to specify each technical aspect of the machine so that it fits the application perfectly.

For example:

If you need a custom machine, then you have come the right place. West Salem Tool designs and builds turnkey custom machinery and equipment. In other words, our company integrates the fluid, electrical, and control and safety systems to provide manufacturers with machines made to spec. We deliver and install at customer’s factories across Wisconsin and the Mid-West.

Need something not shown elsewhere on this website? That’s fine, we tackle new designs all the time. Contact us and start your project today. We’re always willing to put together a proposal and offer a free quote.

To get a better idea of our capabilities, look at more examples of a West Salem custom machine at the youtube channel.

Customers often ask for modified versions of our standard equipment. For example, we’ve made extended length versions of our WTP tube planishing machines, many variations on our 10 ton and 12 ton hydraulic presses, resized tube slotting machines, and welding turntables with custom tooling. We also make large, heavy duty hydraulic presses and CNC drilling machines.

Our machine design skill set includes finite element analysis (stress, heat & fluid). Because experienced toolmakers assemble these machines, we are maintenance-conscious and design for bolt access and ease of disassembly. Design, 3D modeling, and documentation is in Solidworks.

We machine the parts in-house and can modify and iterate a design quickly. Since we design build each part, spares will always be available in the future.