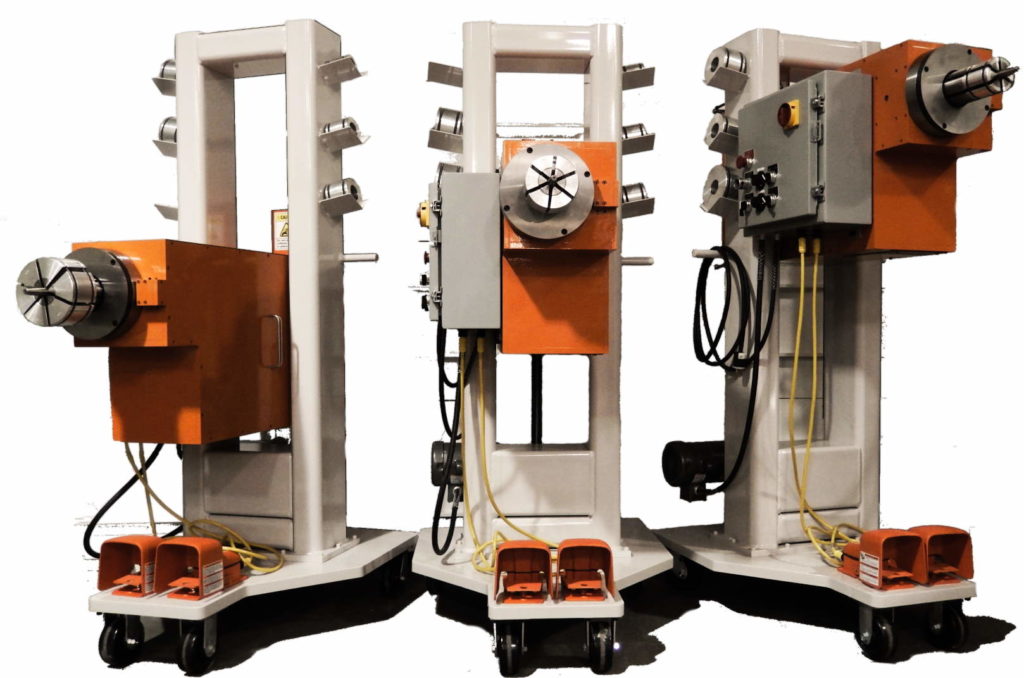

Also known as welding positioners or rotary positions, the AHT series can hold and rotate parts at a cantilevered angle parallel to the ground.

Our AHT-250 adjustable height welding turntables help you make the most of your floor space and improve weld quality.

Why?

Because the welder can stand still, instead of awkwardly shuffling around a circular weld. The operator can also set the rotation speed, which is easily adjusted. For auto-welding, we offer torch mounting options.

AHT-250 Technical Data

This youtube video shows how simple it is to operate these machines. Since our machine works by clamping onto the inner diameter of a tube or pipe section, it doesn’t require wrenches and bolts to load and unload. Instead, you just step on the foot pedal to unclamp the part.

Learn more about our welding turntables here: Welding Turntables Brochure Link.

AUTO TORCH OPTION

Upgrade your machine! A turntable already makes it easy to keep speed and weld angle consistent around a weld. By adding an auto torch mount, you can take it to the next level by locking in the optimal torch position. We often recommend customers get this option.

WELDING TURNTABLES DELIVERED ACROSS NORTH AMERICA

West Salem Tool commonly provides machines and fixtures to customers across Wisconsin and Minnesota, but we deliver farther if needed. Since these machines are reliable and made standard, they do not typically need any extra service or maintenance once built.

Contact us for a quote on a standard AHT-250. Or send in a drawing of your part, and we’ll design a fixture to interface with a turntable. We do CAD design in Solidworks, but we can handle almost any file format.